The engineering team has successfully implemented a project for the installation of a bulk product loading line for a cereal plant. The project was executed on a turnkey basis, taking into account the limited dimensions of the production area and the need to maintain flexible product flows from hoppers — to trucks, big bags, and the packaging line.

Project Goal:

To improve the efficiency of bulk material transportation and loading processes, as well as to optimize the company’s logistics without compromising production flow flexibility.

Key Advantages of the Solution:

Compact and convenient equipment layout;

High productivity — up to 20 tons per hour;

Integration with existing process lines;

Capability for simultaneous loading into different types of containers.

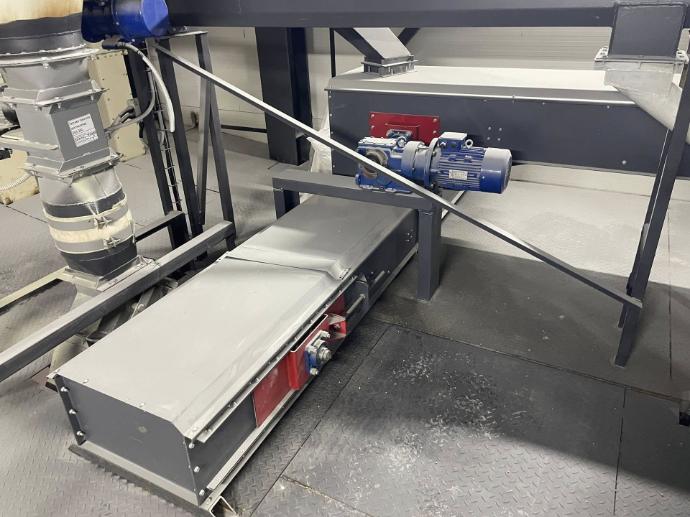

A modern loading system has been created, including two enclosed belt conveyors (18 m and 6 m), three screw conveyors of 2 m each, and distribution valves. The solution ensures stable operation, minimal product losses, and full process automation.

This project demonstrates how maximum production efficiency can be achieved even under limited conditions. The integrated loading system not only accelerates logistics but also enhances the safety and reliability of the plant’s operations.