ECONOMILL Flour-Milling Complexes — For Stable Quality and Precise Grinding

ECONOMILL flour-milling complexes are high-precision industrial systems for producing wheat and rye flour, developed by the Turkish manufacturer Özbaşak Değirmen, a company with over 25 years of experience, 20,000 m² of modern production facilities, and successful installations in 17 countries.

ECONOMILL mills ensure technologically correct grain preparation, multi-stage cleaning, moisture conditioning, and stable grinding performance thanks to optimized 2/4/6-roller systems and precision sifting.

The equipment is engineered to deliver consistent particle distribution, high-quality graded flour, and minimal losses.

START-UP Conveyor Service adapts these complexes to specific production requirements, handles design engineering, installation, commissioning, and—if needed—integrates an external aspiration system as a dedicated engineering module, enhancing process stability, product purity, and equipment longevity.

Ваші болі — наші рішення

Comprehensive Solutions for Your Mill

Turnkey mill

Modernization of mills

Support and service

Формат реалізації проєкту під ключ

Інженерія

Постачання

Монтаж

Запуск і здача в експлуатацію

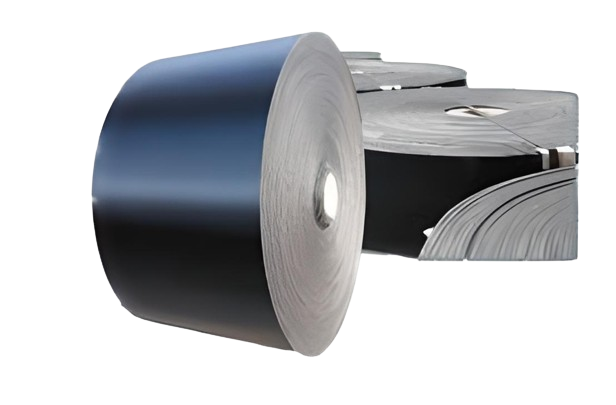

Комплектуючі для борошномельного обладнання

У цьому розділі зібрані комплектуючі для борошномельного обладнання, що представлені в асортименті START-UP. Ви знайдете деталі для валків, сит, підшипників, ременів і інших елементів, які забезпечують безперебійну роботу та високу продуктивність млинів, сортувальних і подрібнювальних ліній.

FAQ — Questions Clients Frequently Ask

An in-house mill lowers production costs and gives full quality control.

ECONOMILL provides high energy efficiency, minimal losses, and stable flour output, which significantly reduces operational expenses.

Typical payback period: 1.5–3 years, depending on processing volume.

30 t/day — farms and local mills

60 t/day — mid-size enterprises with regular production

90 t/day — industrial plants with continuous high-load operation

Yes.

The roller systems allow the production of premium, semi-premium, or special-purpose flour.

Switching between grades is done by changing the sieves and adjusting roller settings.

Base grains: wheat, rye.

Additional (with proper conditioning and sieves): triticale, corn, barley.

It is important to correctly set moisture conditioning and select the correct sieve type for each grain.

Approximate indicators:

-

30 t/day — ~240 kW

-

60 t/day — ~350 kW

-

90 t/day — ~510 kW

Actual consumption depends on grain moisture, cleaning quality, and roller settings.

Stability is achieved through:

-

precise conditioning,

-

multi-stage cleaning,

-

optimized roller parameters,

-

controlled sifting.

This ensures consistent particle size distribution and repeatable quality from batch to batch.

Key signs:

-

inconsistent flour quality,

-

roller overheating,

-

increased dust,

-

reduced throughput,

-

frequent stoppages or repairs.

Modernization typically includes upgrading rollers, sifting systems, automation, and energy modules.

Aspiration removes dust, stabilizes grinding, controls temperature, and keeps all technological zones clean.

Most projects include a dedicated aspiration system engineered according to selected capacity and equipment layout.

Yes.

START-UP performs an audit of grain, facilities, and existing equipment to determine the optimal mill configuration and performance.

Standard mill packages include core processing equipment.

Silos and bins for flour, bran, or grain are selected individually for each project — their parameters depend on throughput, logistics, and available installation space.

Other products

Contact Our Specialist

Elevator Systems

Kostiantyn Bushko

With over 10 years of experience managing engineering projects in the elevator and grain-processing sectors — including design, construction, modernization, technical audits, equipment supply, and capital procurement — I lead technical presales and integrated solutions for elevator facilities at START-UP.

My approach is based on operational reliability, engineering precision, and strategic partnership at every stage of project implementation.