SKIF Packaging Lines

SKIF packaging lines are a modern solution from a European manufacturer based in Slovakia, specializing in industrial dosing and packaging systems for bulk materials.

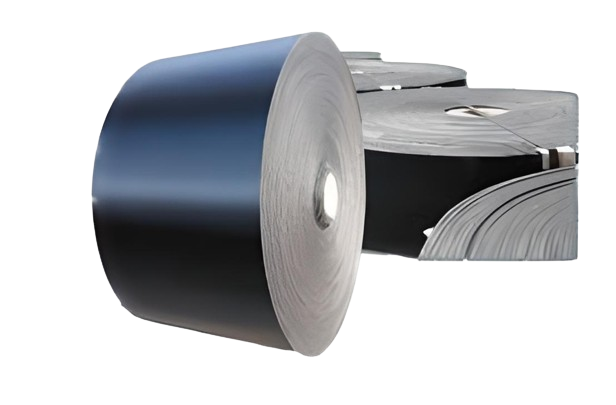

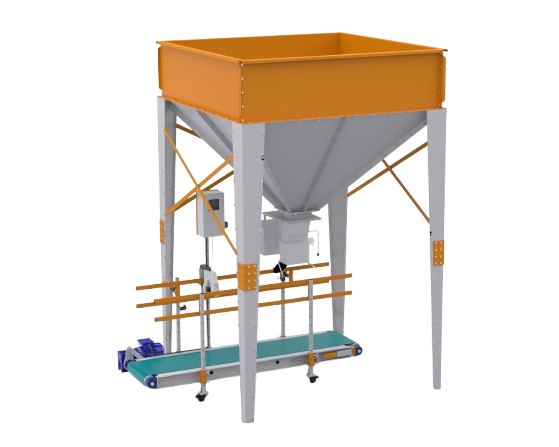

SKIF equipment ensures high dosing accuracy, stable packaging speed, and minimal product loss, operating with 5–50 kg bags and Big-Bags, with seamless switching in just minutes.

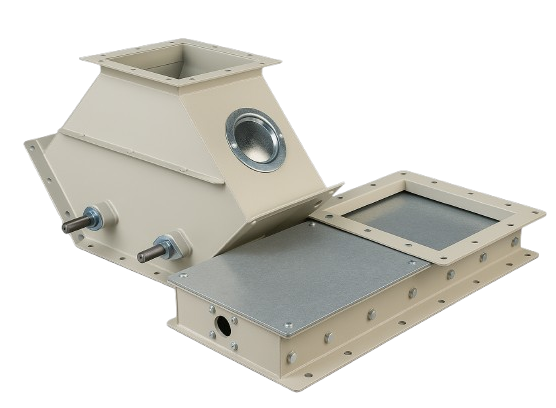

Thanks to automated modules, conveyor bag discharge, a modular hopper, and full integration with aspiration systems, SKIF lines guarantee a clean technological process, reliable operation with no downtime, and predictable packaging quality — highly valued by engineers, technical directors, and production managers.

Your Problems — Our Solutions

Advantages Proven by Numbers

High Dosing Accuracy

±1–2 %

Fast Changeover

2–3 minutes

Minimal Staffing

1 operator

High Line Throughput

up to 300 bags/hour

Clean Process

up to 95% dust removed

Формат реалізації проєкту під ключ

Інженерія

Постачання

Монтаж

Запуск і здача в експлуатацію

FAQ — Questions Clients Frequently Ask

Focus on your peak production load.

If you output 100–200 bags/hour, a standard line with conveyor discharge is sufficient.

If peak loads exceed 250 bags/hour, you need a line with reinforced conveying and automatic stitching.

Yes. The more consistent the product flow from the hopper, the more stable the bag weight.

This is why SKIF uses a modular expandable hopper, which reduces flow interruptions and supports precise dosing.

Yes.

The SKIF dosing unit handles grain, pellets, feed, sugar, coffee, and other bulk materials.

Correct speed and gate settings are the only requirements.

One line.

Switching between 5–50 kg bags and Big-Bags takes only a few minutes.

This is standard SKIF functionality confirmed in technical documentation.

Accuracy is achieved through slide gates, adjustable dosing shutters, and flow control.

This allows weight deviation to remain within ±1–2%, depending on material flow characteristics.

In standard configuration — one operator.

Automated dosing, filling, stitching, and transport significantly reduce manual labor.

Check the gate opening, hopper flow stability, and slide-gate operating mode.

In 90% of cases, fine-tuning the feeding speed resolves the issue.

Yes.

SKIF lines are designed for continuous industrial operation.

Reinforced mechanisms and Big-Bag valves ensure stability under heavy load.

Universal packaging modes, modular hopper design, fast format changeover, high-precision gates, and full integration with START-UP aspiration and conveying systems make SKIF ideal for industrial applications.

Most often: incorrect dosing mode, unstable hopper feeding, lack of aspiration, wrong bag type, or missing calibration.