Chemical Barrier Flash

The Flash chemical barrier is based on the Flash explosion suppression system and operates on a similar principle. It can detect an explosion at an early stage using pressure or flame detectors. Special suppressant powder is then released at multiple points, forming a barrier that prevents flame propagation.

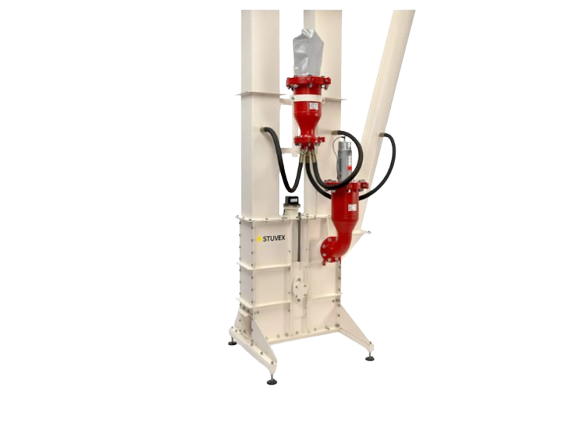

The system is typically used to protect the inlets and outlets of processes such as bucket elevators, chain conveyors, dryers, filters, mills, and others.

Operating Principle

The Flash chemical barrier has a modular design and consists of three main components:

Explosion Detectors – rapidly detect increases in static or dynamic pressure, as well as light intensity (flame).

Controller – manages the interaction between the detector and the suppressant powder cylinder.

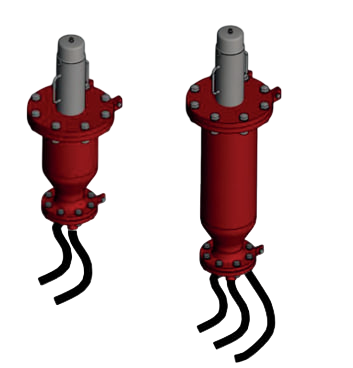

Powder Cylinder and Gas Generator – contains the suppressant powder and one or more outlets to form the protective barrier.

ATEX-certified chemical barrier

Sodium bicarbonate-based suppressant powder, suitable for the food industry

Not subject to PED (Pressure Equipment Directive)

Up to 4 outlets per cylinder

Easy installation on existing equipment

Simple operation and maintenance

Durable modular design

Compliant with EN 14373:2005

Over 20 years of experience across various industries and operating conditions