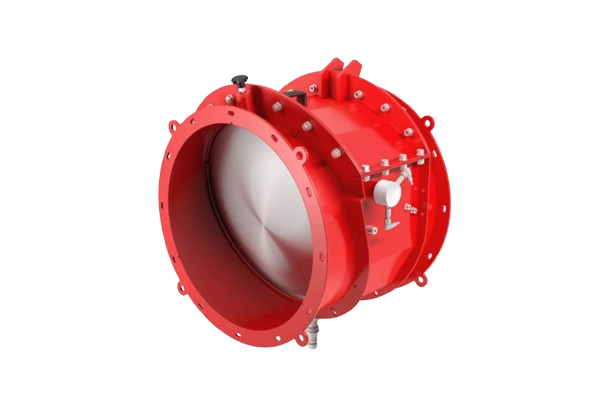

Novex non-return flap valve

The NOVEx II series is a protection system consisting of a passive reverse valve designed to isolate combustible dust explosions. The valves are certified according to ATEX EN 16447:2014 and EN 15089:2009 standards.

NOVEx II is used to prevent the propagation of explosions from dust filters to the inlet of contaminated air or the outlet of cleaned air. For additional filter protection, pressure relief panels or explosion suppression systems can also be applied.

Operating Principle

The NOVEx II valve passively blocks the dust explosion front in the pipeline, isolating the filter and preventing the spread of flame and blast wave. The valve can be installed horizontally or vertically, and the pipe length between the filter and the valve can vary from 5 to 15 meters.

Available in sizes DN71–DN1000

Automatic valve lock in the closed position in the event of an explosion

Housing made of painted steel (MS) or stainless steel (SS 304)

Maximum operating pressure Pmax ≤ 1–2 bar, depending on DN and dust type

Suitable for organic, metallic, and other types of dust

Certified for “Pull” or “Push” type installation

Suitable for protecting clean air in pipelines

Horizontal and vertical installation possible

Adjustable pipeline length between filter and valve (5–15 m)

Compliant with EN 16447 and EN 15089, compatible with NFPA 69:2019 when used with required options

Suitable for dust with very low MIE (≥1 mJ)

Maximum Kst rating up to 305–440 bar·m/s, depending on dust type