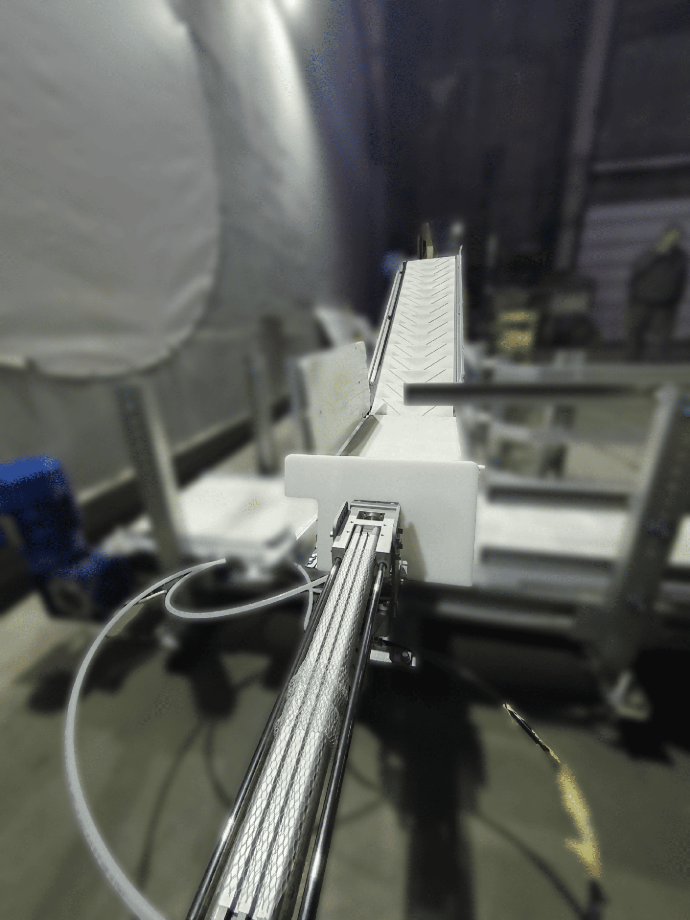

Inclined Conveyors

As part of the completed project, a system of inclined conveyors was developed for the automatic feeding of bags to the palletizer, with remote height adjustment.

The control system includes frequency converters for regulating the belt speed and control units for adjusting the height.

Benefits for the Client

Automation of the Process: The inclined conveyor system significantly simplifies the process of feeding bags to the palletizer, reducing labor costs and increasing productivity.

Adjustable Flexibility: The conveyors are equipped with remote height adjustment, allowing for quick adaptation of the system to various production tasks.

Reliability and Durability: The use of galvanized steel and high-quality materials such as PU belts and KAMOZZI pneumatic pusher systems ensures the durability and resilience of the equipment in aggressive production environments.

Ease of Movement: The conveyors are equipped with wheels, providing convenience in moving them around the workshop, optimizing space, and allowing for easy reconfiguration of work zones.

Performance Flexibility: Gear motors with smooth speed adjustment enable precise system operation tuning based on production requirements.

Control and Monitoring: Frequency converters in the control cabinet allow for precise speed regulation of the conveyors and provide comfortable system management using foot pedals for height adjustment.

Ease of Operation: All components of the system easily integrate into existing production processes, ensuring high operational efficiency and minimal effort for operators.