Available manual, electric, hydraulic, or pneumatic valves.

All steel chains are designed and engineered for long service life and maximum working loads. The chain can be either welded steel or roller type.

The bearing support is made from 1/4 inch (6.4 mm) thick plate and securely fastened in place to ensure maximum strength.

The overhead equipment is made from heavy-gauge steel and welded to the chain.

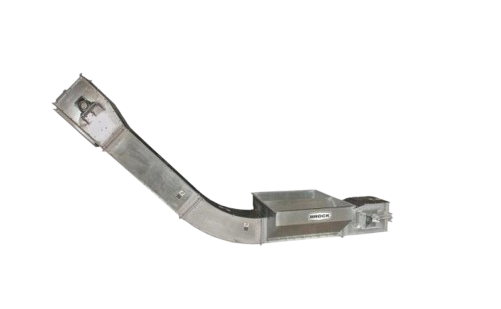

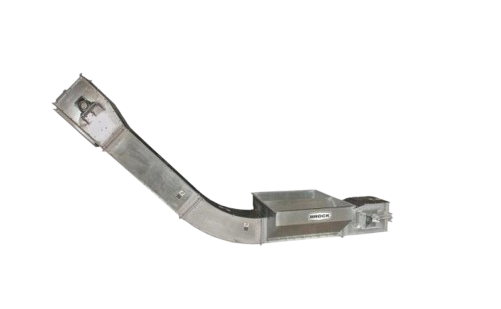

All head, tail, and trough sections are supplied fully assembled for quick on-site installation.

The internal turning trough is bolted in place and can be replaced.

Lower connecting plates for precise alignment on 17-inch (432 mm) tall models. The bolted bottom overlaps on 20-inch (508 mm) tall models and larger.

The lower section of the trough features bolted fastening for ease of maintenance and replacement.

The C-style sprocket is made of flame-treated steel with a hardened rim. A split style is optional.

Screw-type tensioning fasteners for longer service life.

Turned, ground, and polished shafts are made of 1045 steel.

Wear-resistant bottoms, turning troughs, and side covers are available in various thicknesses.

Curved tail sections and tail ends with tight tolerances are available as an option.