RINGSPANN HUB CONNECTIONS

Hub connections allow for co-axial installation of shafts and components onto shafts with minimal effort, while still enabling easy disassembly. The use of hub connections is justified when there is a need to quickly and reliably fix two shafts, a shaft and a wheel (pulley, drum, disc, etc.), or a shaft within a bore.

Advantages and Applications of Ringspann Hub Connections

Structurally, such a connection consists of movable parts, with the compressive or expansive force applied through tightening screws, bolts, or supporting springs. The advantages of hub connections include:

– Simple design;

– Easy installation and disassembly;

– No need for shaft machining or weakening by cutouts (unlike keyway, spline, and other connections);

– Ability to adjust the fixation force and position on the shaft.

These advantages provide a wide range of applications for hub connections and their constructive feasibility, making them one of the most effective solutions in their field.

Ringspann offers hub connections for various applications, including:

CLAMPS

Clamps can be designed in a two-part or three-part construction.

Two-part construction

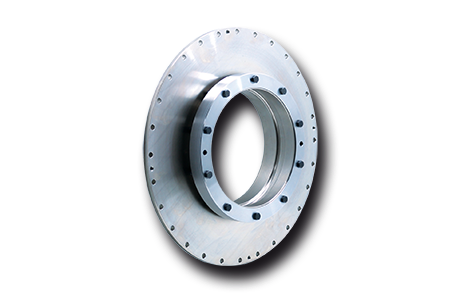

Heat Shrink Discs RLK 608

Heat Shrink Discs RLK 608 E

Heat Shrink Discs RLK 606

Discs RLK 606 and RLK 608

Three-part construction

Heat Shrink Discs RLK 603

Heat Shrink Discs RLK 603 K

Heat Shrink Discs RLK 603 S

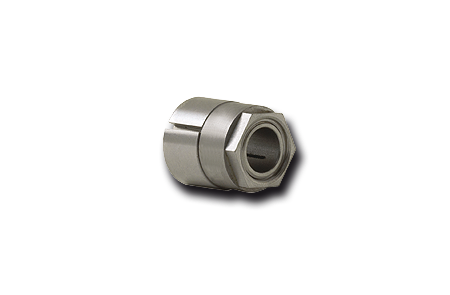

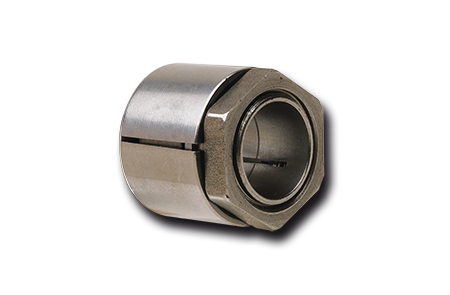

Conical clamping elements, Star-shaped elements for frequent clamping and release

RLK 110

RLK 110 K

RLK 130

RLK 131

RLK 132

RLK 133

RLK 133 TC

RLK 136 TC

RLK 235 TC

RLK 250

RLK 250 L

RLK 350

RLK 402 TC

RLK 404

RLK 404 light

RLK 404 TC

RLK 404 TC light

Trantorque Mini – metric

Trantorque OE – metric

RLK 200

RLK 300

Small axial width

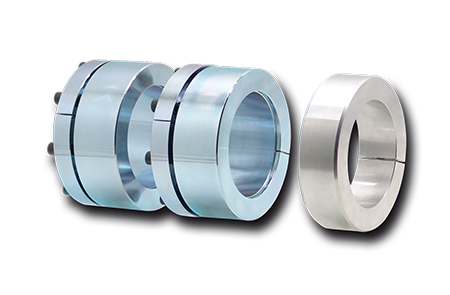

CLAMPING SYSTEMS FOR HIGH-TORQUE ENGINES, STAR WHEELS WITH SPRING WASHERS

Clamping systems for high-torque motors include solutions for integrated high-torque motors, complete high-torque motors SIEMENS 1FW3, complete high-torque motors, and star wheels with spring washers, designed for free mounting on ball bearings.

For Integrated High-Torque Motors

RTM 601 Clamping Systems

for Rotor Installation and Centering

For Complete High-Torque Motors SIEMENS 1FW3, For Complete High-Torque Motors

RTM 607 Clamping Systems for Installation and Centering of High-Torque Motors

RTM 608.1 and RTM 608.2 Clamping Systems for Installation and Centering of High-Torque Motors

RTM 134.1 and RTM 134.2 Clamping Systems for Installation and Centering of High-Torque Motors

STAR WHEELS WITH SPRING WASHERS

Star Wheels with Spring Washers are designed for free mounting on ball bearings.

For Free Mounting on Ball Bearings

Star wheels with spring washers