Process fire extinguishing

Industrial fires and dust explosions are a constant threat to facilities worldwide. Such incidents not only result in injuries or fatalities but also cause significant material damage and production downtime. Every year, millions of dollars are lost due to these events. Therefore, it is crucial to implement preventive measures that stop fires and explosions before they occur. One highly effective solution is the modern spark detection and suppression system from GreCon, offered by Stüvex International.

Operating Principle

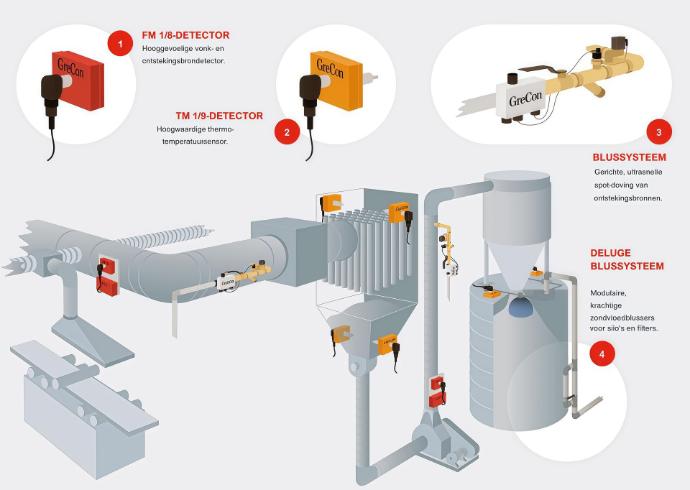

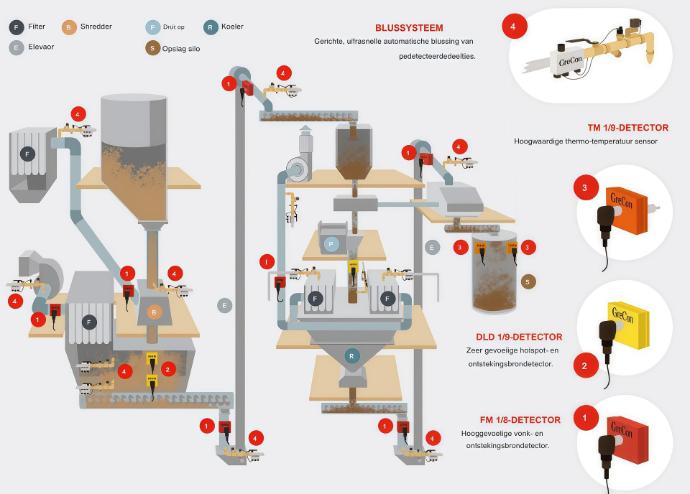

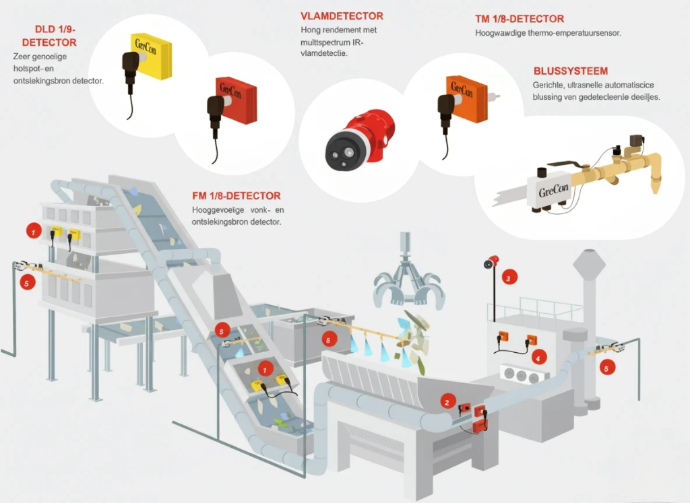

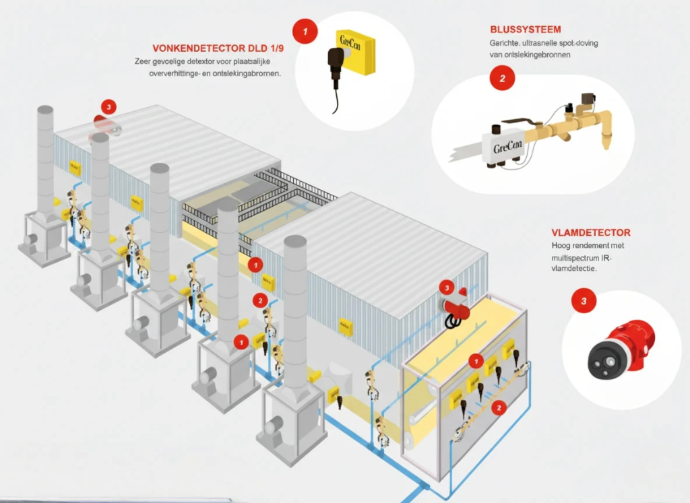

The GreCon system is based on detecting particles that could cause ignition — such as sparks or hot “black” particles in production streams. Detected particles are extinguished within milliseconds, before they can trigger a fire or dust explosion.

At the heart of the system is the control unit, which performs two key functions: detection and automatic suppression. This approach allows GreCon to provide preventive protection by eliminating ignition sources at an early stage.

Detection and Control of Ignition Sources

Sparks and hot particles are the primary sources of ignition. The human eye can only see them at temperatures of around 700°C and above. However, most combustible materials ignite at much lower temperatures. This is why invisible “black” hot particles — generated, for example, by friction or metal components — can create serious hazards.

The GreCon system is effectively applied at various stages of production:

Filtration

Grinding

Pneumatic transport

Mechanical conveyors

Drying belts

Industries Where the System is Particularly Relevant

Wood processing (furniture, MDF, OSB, plywood)

Recycling (metal, paper, plastic, rubber)

Heat and energy plants (biofuel, pellets)

Food industry (flour, sugar, coffee, cocoa)

Chemical industry (raw materials, fertilizers, paints, plastics, cosmetics)

Pulp and paper industry

Textile industry

Effective prevention of fires and dust explosions

Reduced downtime and material losses

Minimized false alarms

Integration capability with any production process

Enhanced personnel safety and improved production reliability

BESCHERMEN VAN UW AFZUIGSYSTEMEN IN DE HOUTINDUSTRIE

BESCHERMEN VAN UW INSTALLATIE IN DE VOEDINGSMIDDELEN SECTOR

BESCHERMING VAN UW SHREDDER, GRANULEER- EN TRANSPORTSYSTEMEN IN DE RECYCLINGSECTOR

PREVENTIEVE DROGER BESCHERMING MET HET BEWEZEN GRECON-CONCEPT_0