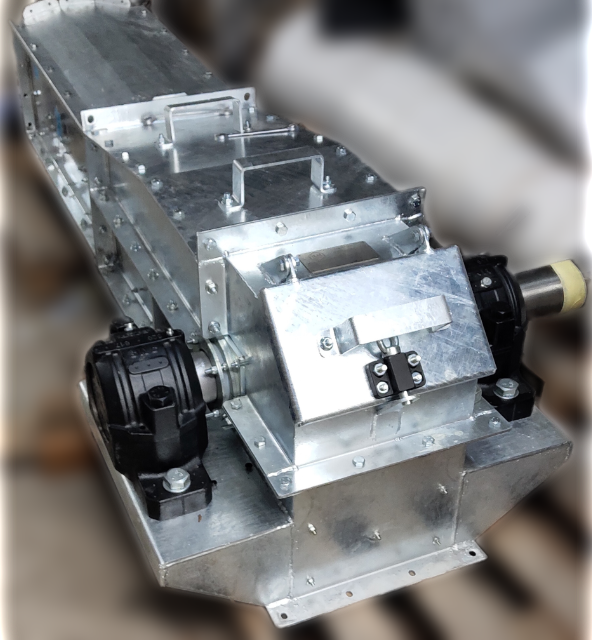

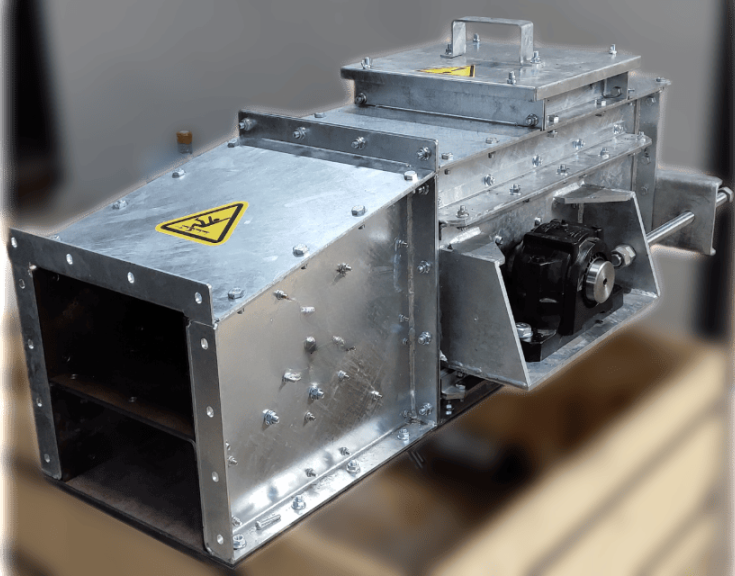

Chain Conveyor for High-Performance Pellet Transportation

As part of the project, a chain conveyor with a capacity of 12 tons per hour was developed and implemented. Designed in a "gooseneck" configuration, the conveyor is intended for transporting pellets (seed granules).

Benefits for the Client

High Productivity: The conveyor supports pellet transportation at a capacity of up to 12 tons per hour, optimizing production processes and improving operational efficiency.

Reliable Performance: The SEW gear motor ensures stable and uninterrupted operation, even under significant loads.

Durability and Longevity: The John King 81xHH chain offers exceptional load resistance, reducing the risk of failures or downtime.

Corrosion Protection: The conveyor body is made of 09G2S steel with hot-dip galvanization, ensuring long-term durability even in aggressive environments.

Wear Protection: The inner surfaces are lined with 4-6 mm thick Hardox 450 material, safeguarding against abrasive wear and extending the equipment's lifespan.

Efficiency in Production: The conveyor is designed to handle pellets and granular materials efficiently, ensuring reliable transportation without delays or damage.

Cost Reduction: The reliability and durability of the equipment minimize maintenance and repair costs, making the investment economically advantageous.