Full-Cycle Engineering Feed-Mill Lines — From Grain to Finished Feed

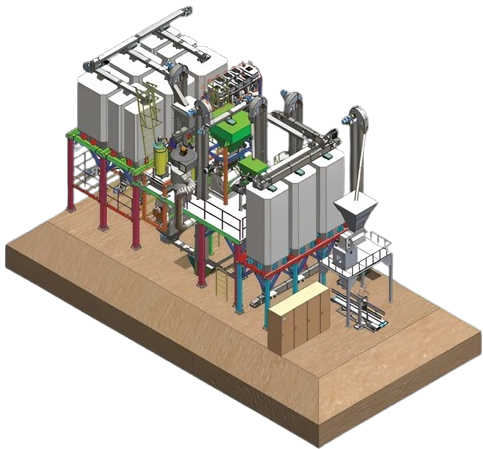

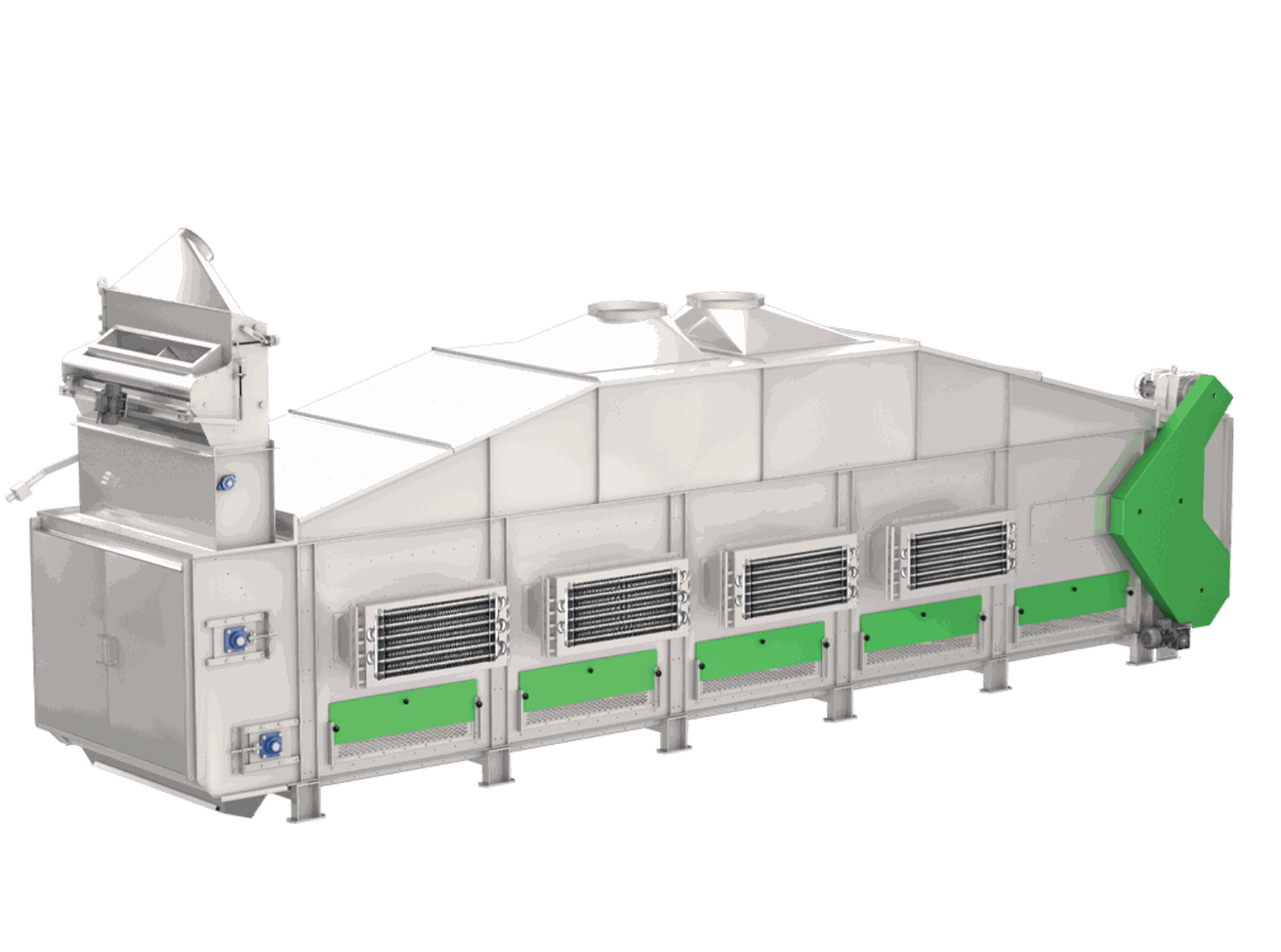

A feed mill is a complex system of high-tech equipment designed to process grains, legumes, and other crops into balanced feed, covering the entire cycle: dosing, grinding, mixing, pelletizing, and packaging.

START-UP Conveyor Service, together with the global manufacturer Özbaşak Değirmen, designs and implements feed-mill lines for farms, livestock complexes, and industrial plants, ensuring recipe accuracy, consistent batch quality, automated processes, and a European level of safety.

Integration of the feed-mill line with conveying systems, aspiration, and STIF safety technologies ensures a safe, stable, and continuous production process.

Thanks to precise dosing, controlled granulometry, and minimal raw-material losses, customers benefit from lower feed cost (up to –25%), predictable productivity, and fast return on investment.

Your Problems — Our Solutions

Technological Processes

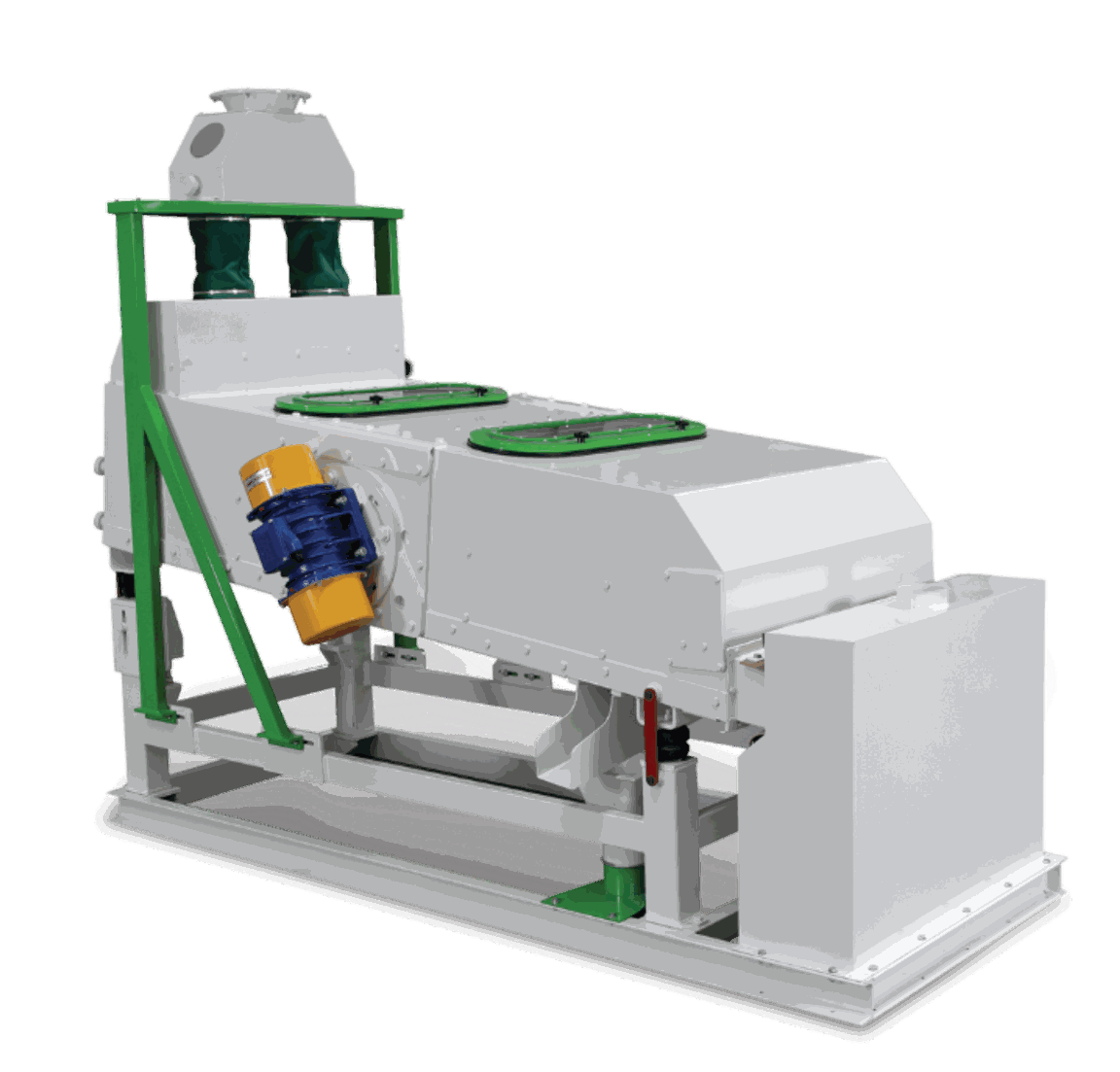

Milling and Dosing

Packaging Line

Pelletizing

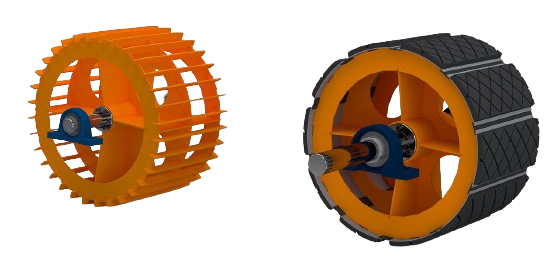

Flaking

Формат реалізації проєкту під ключ

Інженерія

Постачання

Монтаж

Запуск і здача в експлуатацію

FAQ — Questions Clients Frequently Ask

If your feed consumption exceeds ~0.5 t/h, an in-house line is often economically justified: up to –25% lower feed cost, full control over formulations, and a 12–24 month payback period.

Вибір продуктивності залежить від добового споживання кормів. Якщо господарство використовує 13 т/добу, раціонально встановлювати лінію 5 т/год із роботою в одну зміну або 3 т/год у дві зміни.

Комбікормовий завод 10 т/год доцільний для агрохолдингів із великим поголів’ям або для комерційного продажу кормів. Надмірна потужність збільшує інвестиції та термін окупності, тому проектування має базуватися на реальних розрахунках.

Вартість комбікормового заводу під ключ визначається не лише продуктивністю (3–20 т/год), а й економічним навантаженням господарства. Наприклад, при поголів’ї 1000 дійних корів середнє споживання комбікорму може становити близько 13 т/добу. У такому випадку оптимальною буде лінія 5–10 т/год із резервом потужності.

Будівництво власного комбікормового заводу дозволяє знизити собівартість кормів до 20–30% завдяки прямій закупівлі сировини та контролю рецептури. Остаточна вартість залежить від комплектації, автоматизації та енергоефективності обладнання.

Use IE4–IE5 drives, optimize conveying speed, minimize idle cycles —

overall energy reduction up to –15%.

При щоденному споживанні 10–15 т комбікорму власний комбікормовий завод дозволяє економити сотні тисяч гривень щомісяця за рахунок різниці між закупівельною ціною готового корму та собівартістю власного виробництва.

Наприклад, навіть економія 500–800 грн на тонні при обсязі 300–400 т на місяць формує значний грошовий потік. За таких умов окупність комбікормового заводу може становити 1,5–3 роки залежно від інвестиційної моделі.

Aspiration, explosion-relief panels, airlocks, temperature and speed sensors, CE/ATEX compliance.

We include all required systems as part of our standard solutions.

You need recipe correction, moisture control, and pre-screening before grinding.

We offer modules for raw-material analysis and adaptive feeding.

Underestimating aspiration needs, selecting equipment without reserve capacity, manual dosing, incorrect conveying layout, lack of service access.

We eliminate these risks at the engineering stage.

Typical timeframe: 2–6 months, depending on project scale, logistics, and facility condition.

Poultry — 2–4 mm

Swine — 4–6 mm

Cattle — larger pellets or flakes

Our hammer mills support the full 0.2–5 mm granulometry range.

Other products

Contact Our Specialist

Elevator Systems

Kostiantyn Bushko

With over 10 years of experience managing engineering projects in the elevator and grain-processing sectors — including design, construction, modernization, technical audits, equipment supply, and capital procurement — I lead technical presales and integrated solutions for elevator facilities at START-UP.

My approach is based on operational reliability, engineering precision, and strategic partnership at every stage of project implementation.