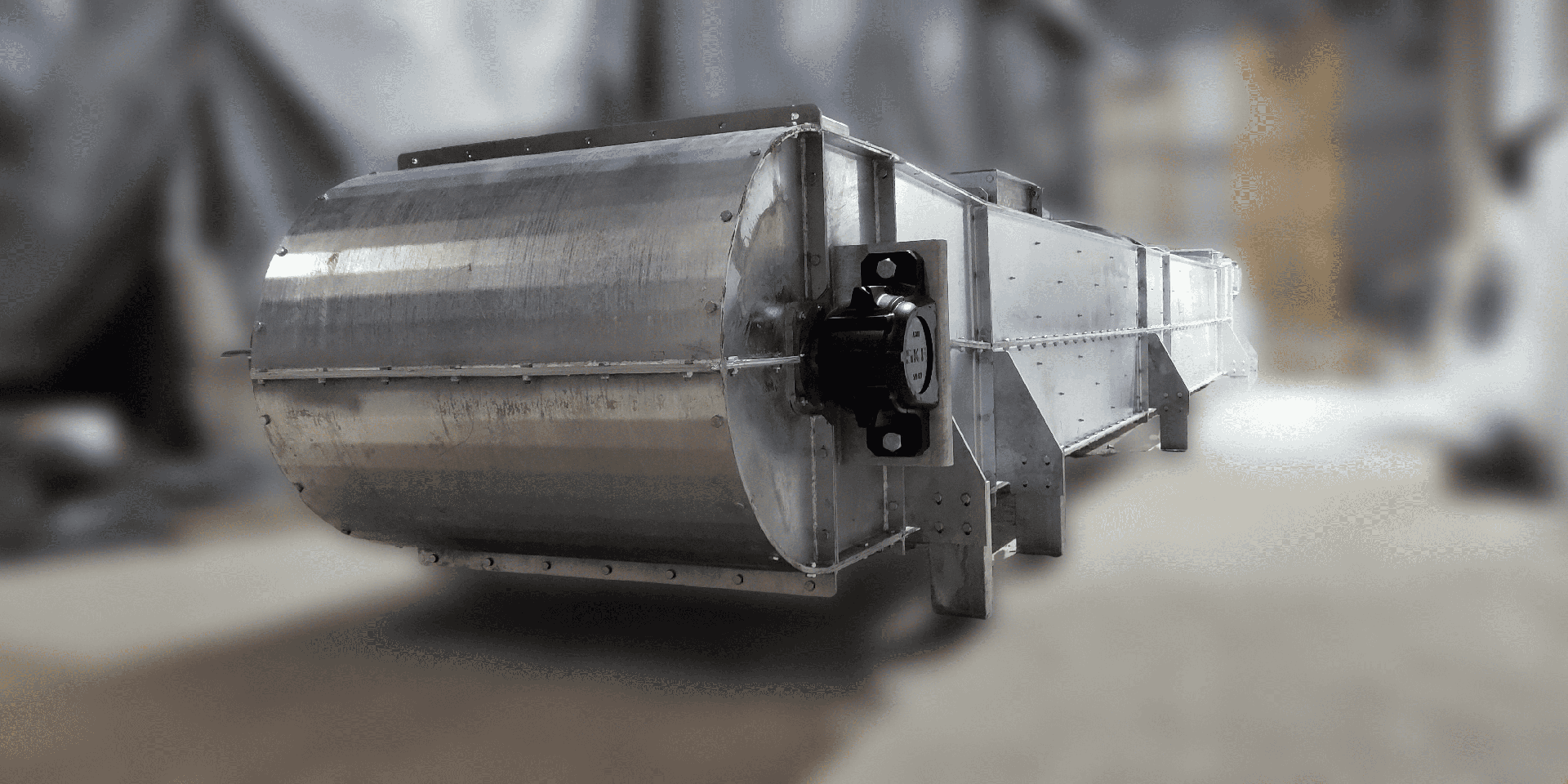

High-Performance Chain Conveyor for Seed Processing

As part of the project, a 12 t/h capacity "goose neck" type chain conveyor was developed and implemented for transporting seed pellets. The conveyor is equipped with an SEW gear motor, John King 81xHH chain, and Hardox 450 lining, ensuring reliability, durability, and efficiency in aggressive operating conditions.

Benefits for the Client

High Productivity: The conveyor ensures the transportation of pellets with a capacity of up to 12 t/h, optimizing production processes.

Reliable Operation Under Load: The use of an SEW gear motor guarantees stable and efficient operation of the equipment even under intense usage conditions.

Durability and Wear Protection: The Hardox 450 lining, 4-6 mm thick, protects internal surfaces from wear, extending the equipment's service life.

Resistance to Aggressive Conditions: The 09G2S steel body with hot-dip galvanizing provides corrosion resistance, making the conveyor suitable for operation in harsh environments.

Reliable Chain: The John King 81xHH chain is known for its strength and durability, reducing downtime risks and lowering maintenance costs.

Versatility: The conveyor is suitable for transporting seed pellets and other bulk materials, adapting to the needs of various production processes.

Cost-Effectiveness: The reliability and long service life of the equipment reduce operational costs, making it a cost-effective investment in production capacity.