Brock Silos — Long-Life Solutions for Safe and Stable Grain Storage

BROCK silos are high-strength industrial structures with increased wall heights and expanded storage capacity, engineered for stable and secure grain preservation.

A reinforced roof structure, thicker wall sheets, high-grade corrosion-protected bolted connections, and optimized vertical seams ensure durability and reliability even under challenging operating conditions.

The silo design meets or exceeds current industry standards, while BROCK’s integrated conveying and aeration solutions minimize grain damage and increase energy efficiency.

Combined with START-UP engineering, this is a comprehensive system that delivers predictable, precise, and failure-free performance for decades.

Your Problems — Our Solutions

Comprehensive Solutions for Your Grain Facility

Grain Storage

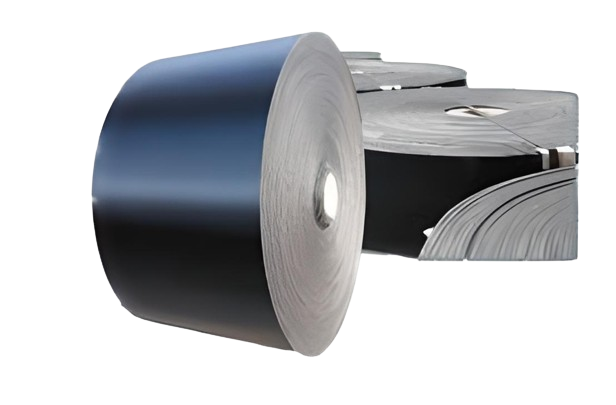

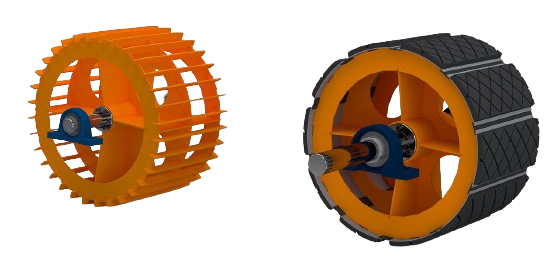

Grain Conveying

Drying

Формат реалізації проєкту під ключ

Інженерія

Постачання

Монтаж

Запуск і здача в експлуатацію

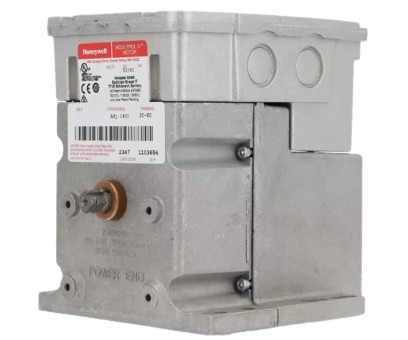

Запчастини для комплексів зернообробки та елеваторів BROCK

У цьому розділі ви знайдете оригінальні та сумісні запчастини для обладнання, що входить до комплексів зі зберігання, транспортування та сушіння зерна BROCK від START-UP. Тут представлені комплектуючі для силосів, норій, транспортерів, аераційних і вентиляційних систем, що забезпечують стабільну роботу зерносховищного обладнання та мінімізують простої.

FAQ — Questions Clients Frequently Ask

Capacity is calculated based on daily intake, shipping rate, and planned storage duration.

After auditing your site, we determine the optimal silo diameter and height to avoid bottlenecks and ensure a reserve of storage capacity.

Self-heating occurs due to insufficient airflow and localized “hot spots.”

The solution is proper aeration, uniform air distribution, and temperature monitoring.

BROCK + START-UP integrate fans, aerators, and probing sensors that detect risks at an early stage.

Main causes are temperature differences, poor ventilation, or an incorrectly selected silo type.

BROCK’s Eave Vent System reduces static pressure and removes humid air, while we design the ventilation and capacity setup that eliminates condensation.

Key signs include unstable aeration, worn ventilation channels, lack of temperature sensors, and increased grain losses.

START-UP performs a full audit and recommends structural reinforcement, ventilation upgrades, or monitoring system integration.

Yes. SKIF bucket elevators, belt, and chain conveyors are fully compatible with BROCK silos.

We design the infeed, discharge, and aspiration interfaces to avoid overload and material loss.

Via probing systems and digital monitoring platforms.

Sensors track temperature at multiple points, and the system alerts operators to deviations.

START-UP integrates the optimal monitoring system based on silo capacity.

Yes. BROCK structures meet international engineering standards, and START-UP provides all documentation required for audits and trading inspections.

Key factors: proper aeration, temperature control, correctly selected silo volume, and elimination of “dead zones.”

BROCK ensures high-quality airflow, while START-UP configures operating modes and control systems.

Time depends on the diameter, height, and number of silos.

On average — from several weeks to several months.

START-UP works on an engineering readiness model, ensuring predictable and delay-free execution.

Yes. BROCK silos are engineered with future expansion in mind.

START-UP initially allocates space for additional bins, conveying lines, and foundation requirements.

Other products

Contact Our Specialist

Elevator Systems

Kostiantyn Bushko

With over 10 years of experience managing engineering projects in the elevator and grain-processing sectors — including design, construction, modernization, technical audits, equipment supply, and capital procurement — I lead technical presales and integrated solutions for elevator facilities at START-UP.

My approach is based on operational reliability, engineering precision, and strategic partnership at every stage of project implementation.