SKIF Aspiration Systems — Clean Air, Stable Production

Системи аспірації SKIF — це високотехнологічні інженерні рішення європейського рівня, розроблені для промислової аспірації та транспортування сипучих матеріалів. Комплекси забезпечують ефективне видалення пилу, стабільну роботу обладнання та оптимізоване енергоспоживання у безперервних виробничих процесах.

Рішення SKIF застосовуються у промислових галузях з підвищеними вимогами до безпеки, екологічності та збереження продукту. Ключовими перевагами є точні інженерні розрахунки, адаптація під реальні технологічні процеси та використання європейських компонентів, що забезпечує відповідність директивам CE, ATEX і стандарту EN ISO 13849.

Аспіраційні системи SKIF проєктуються для роботи у вибухонебезпечному середовищі, де концентрація пилу може у кілька разів перевищувати допустимі норми, а розвиток вибуху відбувається протягом десятків мілісекунд. Для підвищення рівня безпеки обладнання може комплектуватися інтегрованими рішеннями вибухозахисту та моніторингу STIF (Франція), зокрема панелями розвантаження, зворотними клапанами, датчиками іскор та контролю тиску. Це дозволяє своєчасно виявляти джерела займання, локалізувати вибух у початковій зоні та забезпечувати відповідність актуальним вимогам європейського законодавства без необхідності додаткових конструктивних доопрацювань.

Your Problems — Our Solutions

Aspiration is not just dust removal, but a complete technological process that determines the safety, efficiency and quality of production.

Filtration System Range

Uni-f ™

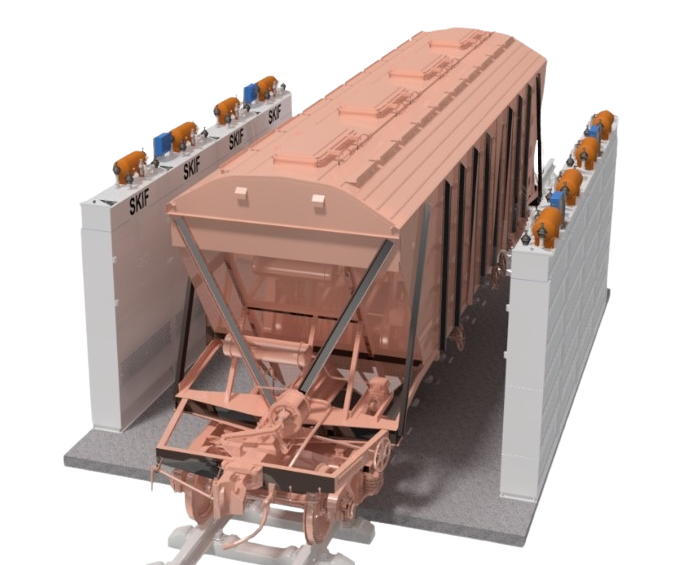

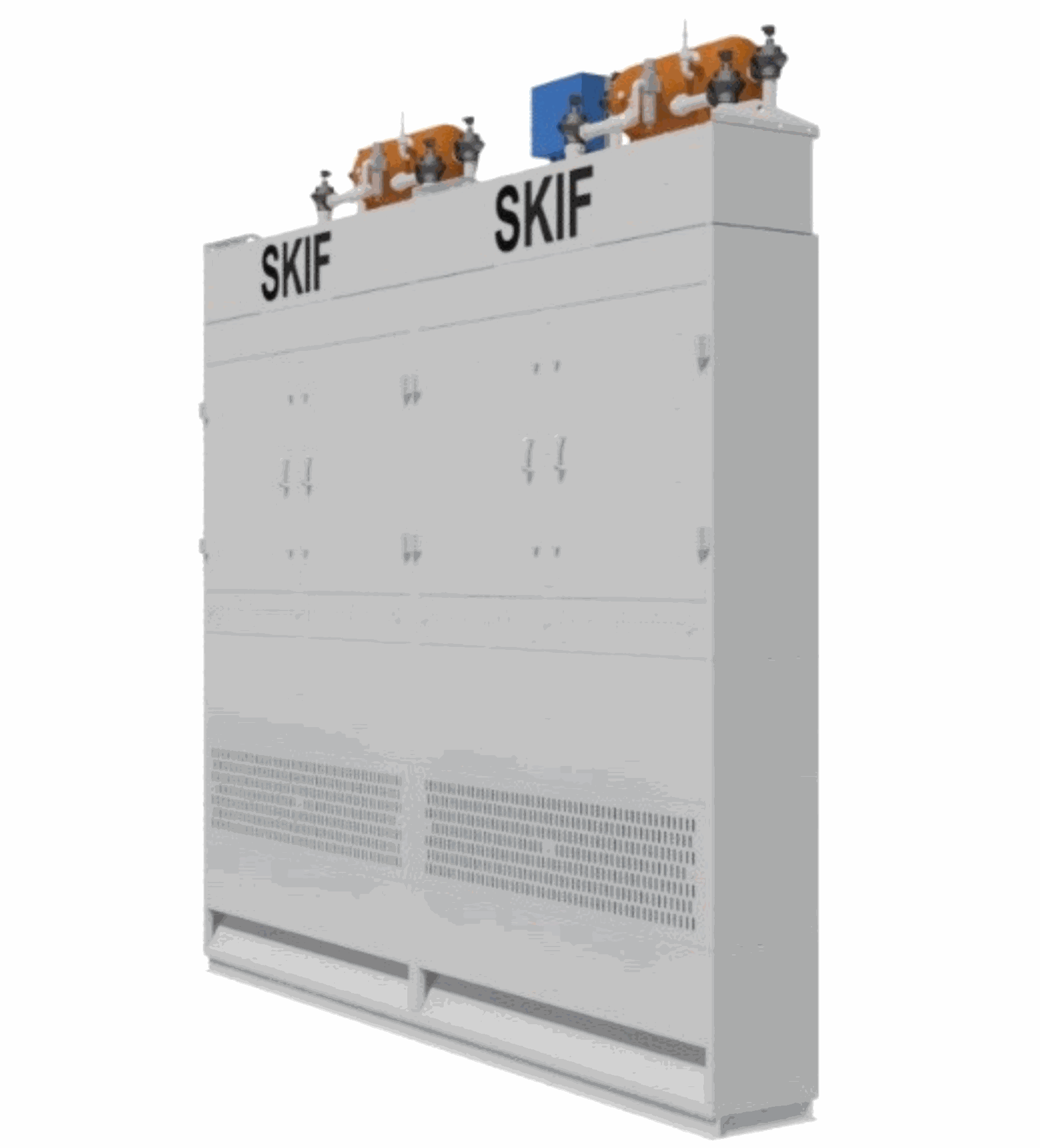

Unload-f ™

Cyclo-f ™

Cas-f ™

Формат реалізації проєкту під ключ

Інженерія

Постачання

Монтаж

Запуск і здача в експлуатацію

FAQ — Questions Clients Frequently Ask

We evaluate the actual dust concentration, ΔP stability, filter condition, and fan performance.

If dust appears in conveying zones, ducts clog frequently, or ΔP fluctuates significantly, the system no longer meets standards and requires modernization.

In such cases, we recommend a dust-generation audit.

This depends on the product type, line capacity, and dust load.

SKIF designs solutions based on:

-

Uni-F — for most elevator and conveying points

-

Cas-F — for fine and problematic dust < 5 μm

-

Unload-F — for loading/unloading zones

-

Cyclo-F — for pre-separation on large flows

-

High-efficiency fans

-

STIF explosion protection

After analyzing your process, we select the optimal system with an airflow capacity from 500 to 72,000 m³/h.

For a correct aerodynamic design, we require:

-

line capacity (t/h or m³/h);

-

material type (grain, flour, feed, shavings, etc.);

-

layout of process units (elevators, conveyors, separators);

-

duct lengths and heights;

-

information on existing filters;

-

ATEX zoning data.

Based on this information, we calculate airflow, ΔP, and select the appropriate filter type.

Service life depends on dust type and ΔP stability.

In SKIF systems, thanks to pulse-jet regeneration and high-quality filter media, the element lifetime is up to 2× longer than in standard solutions.

Recommended checks:

-

ΔP check — once per week

-

scheduled maintenance — once per quarter

Yes. In most cases, full replacement is not necessary.

Effective modernization options include:

-

adding Cyclo-F units before existing filters;

-

replacing old filters with modern Uni-F / Cas-F systems;

-

upgrading to a high-efficiency fan;

-

optimizing ductwork and stabilizing ΔP.

In around 60% of cases, modernization provides the same effect as a new system but at a significantly lower cost.

Key performance indicators:

-

up to –30% energy savings due to proper aerodynamics;

-

reduced product losses (dust returned to the product flow);

-

extended filter lifetime;

-

less downtime from clogging and overloads;

-

ATEX compliance → avoidance of fines and production shutdowns.

On request, we provide a preliminary ROI calculation.

It depends on line capacity, material type, and current equipment condition.

Typical payback period: 8–24 months due to reduced energy consumption, lower product losses, and fewer stoppages.

Selection depends on:

-

dust type;

-

particle size;

-

temperature;

-

ATEX requirements;

-

required airflow.

Typical applications:

-

Uni-F — grain, compound feed, conveying points

-

Cas-F — fine, explosive dust

-

Unload-F — high-precision local aspiration

-

Cyclo-F — pre-separation on large flows and filter protection

Other products

Contact Our Specialist

Aspiration & Explosion Safety

Artem Morozov

Since 2017, I have been working with solutions for agro-industrial, feed-mill, and milling facilities — from dust-generation audits to the implementation of aspiration and explosion-protection systems.

At START-UP, I am responsible for equipment selection, system design, STIF technologies, and full project support.

My approach is based on ATEX, CE, and ISO compliance, engineering precision, and predictable system performance.