SKIF Bucket Elevators — Engineering Precision and Proven Energy Efficiency

The intelligent vertical conveying system for bulk materials, developed by the European company SKIF (Slovakia), combines high energy efficiency, lightweight structural components, and a comprehensive safety architecture compliant with EU requirements.

Thanks to optimized kinematics, lightweight metal structures, and high-precision STIF sensors (temperature, speed, blockage, and critical belt elongation ≤0.8%), SKIF bucket elevators operate with exceptional stability, ensure accurate equipment condition monitoring, and consume 10% less energy than standard market solutions.

Every elevator component is engineered in Slovakia according to the principles of minimal wear, balanced dynamic loads, and maximum reliability. This guarantees a longer service life, fewer unplanned stoppages, and lower operating costs throughout the entire equipment lifecycle.

Your Problems — Our Solutions

Advantages Proven by Numbers

Energy Efficiency

–10%

Higher Reliability

×8

Reduced Product Losses

–3 %

Safe Operation

100 %

Warranty

5 Years

- ffffffffff

- fsЩоб ваш контент був успішним, він повинен бути корисним для ваших читачів.

- gdfgf

- dfd

- gdtg

- hng

Почніть з клієнтом - з'ясуйте, чого вони хочуть і дайте їм це.

FAQ — Questions Clients Frequently Ask

Focus on three key factors:

1️⃣ lifting height,

2️⃣ throughput (t/h),

3️⃣ required explosion-protection level.

Our engineers will help you select the optimal model based on your material type and production volume.

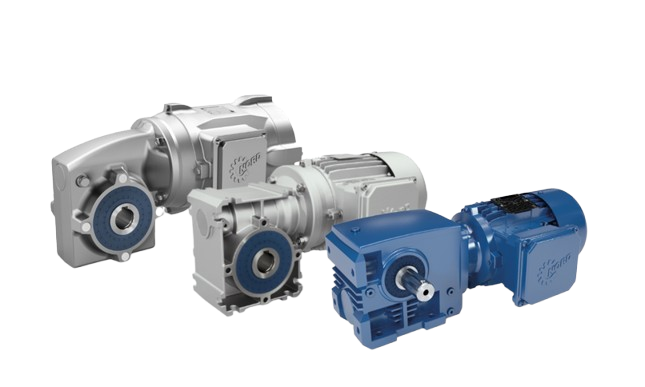

Energy efficiency is achieved through two engineering solutions:

1) Optimized bucket kinematics, which reduce air and material resistance.

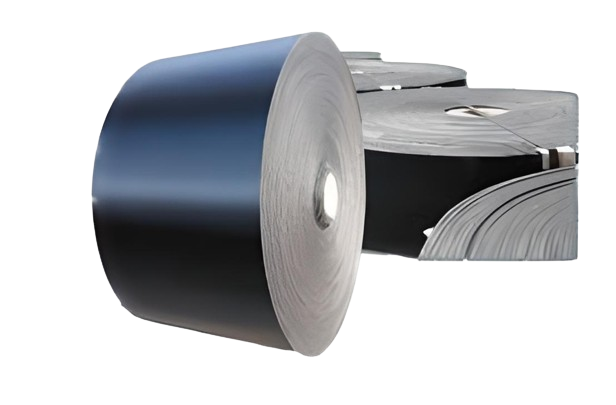

2) STIF Jet Series belts with a lower elongation coefficient (0.8%), reducing load on the motor and drive system.

Yes. ✅

We can retrofit your existing elevator with STIF SensorJet / Vigibelt® sensors, new belts, and explosion-protection elements.

This provides the performance of a “new” system with minimal investment.

No.

It is also used for conveying feed, meal, pellets, cement, granules, agro-mixes — any bulk materials.

It features a sealed construction, antistatic STIF Jet Series belt, specialized casings, and temperature-control sensors.

This prevents dust ignition and explosions — even under heavy-load operation.

We use high-precision STIF SensorJet and Vigibelt® sensors.

They monitor:

• temperature (overheat prevention),

• speed (slip control),

• belt alignment (preventing damage).

This is a predictive safety system, not just a simple alarm.

The price depends on height, capacity, and configuration.

Thanks to –10% energy savings and 8× fewer downtime events, the payback period is 12–18 months.

💡 You can calculate your savings using the payback calculator on our website.

With proper maintenance — over 10 years.

Components from STIF, SKIF, and ARTEGO ensure long-term durability even in continuous 24/7 operation.

Формат реалізації проєкту під ключ

Інженерія

Постачання

Монтаж

Запуск і здача в експлуатацію

Implemented projects: Bucket elevators

Every case is a proven solution — not an experiment.

Our SKIF bucket elevators operate at grain elevators, feed mills, and port terminals across Ukraine, delivering reliability, explosion protection, and up to –10% energy savings.

The intelligent monitoring system with STIF sensors controls temperature, speed, and blockages, while the belt with controlled 0.8% elongation ensures stable, continuous operation with zero unplanned downtime.

See for yourself — these are real projects where engineering precision translates directly into measurable results.

Харчові норії SKIF з нержавіючої сталі

Харчові норії — це спеціалізована лінійка вертикальних транспортерів для харчової промисловості, виготовлена повністю з нержавіючої сталі AISI 304 або AISI 316. Конструкція розроблена для стабільного транспортування борошна, круп, цукру, солі, какао, преміксів, добавок та інгредієнтів без ризику забруднення, втрати продукту або пошкодження структури.