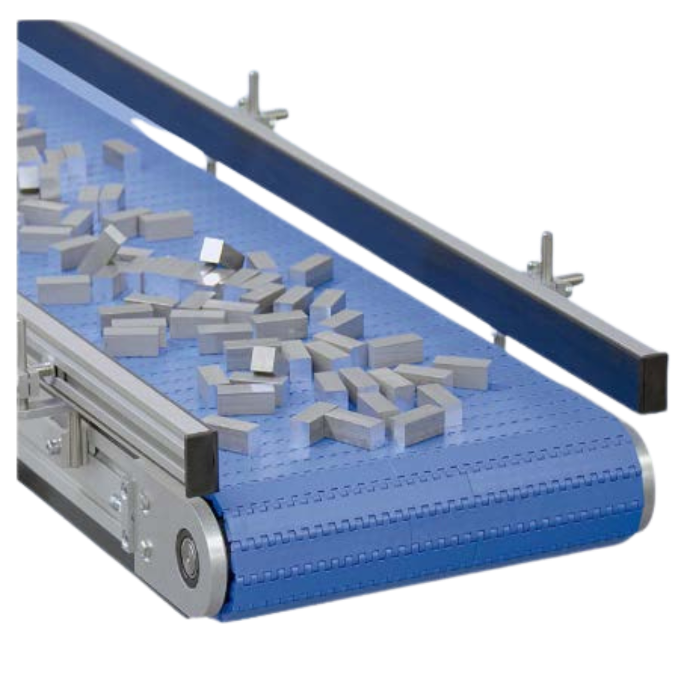

START-UP Light-Duty Conveyors — Stable Performance With Zero Belt Drift

START-UP light-duty conveyors are modular transport systems designed for precise and stable movement of packaged and unit products in environments where hygiene, minimal belt elongation, energy efficiency, and low noise levels are critical.

The design is based on a lightweight, high-rigidity frame and PU/PVC belts with controlled deformation parameters, ensuring accurate product flow and extended service life.

The use of UHMW-PE guides, IE3–IE4 motor-gear units, and food-grade AISI 304/316 materials provides a combination of advantages that make these conveyors ideal for the food, pharmaceutical, and packaging industries: stable belt tracking, hygiene compliance, low operating costs, and the ability to scale the line without altering the core design.

Your Problems — Our Solutions

Advantages Proven by Numbers

Stable Belt Tracking

≤ 0,8%

Reduced Energy Consumption

10–18%

Noise Level

< 65 дБ

Fast Cleaning

≤ 3 хв

Engineering Precision

±2 мм/м

FAQ — Questions Clients Frequently Ask

Start by defining the type of product (moisture, fat content, abrasiveness), then determine the required belt width and speed.

For food-contact zones, use PU food-grade belts (HACCP / EU 1935/2004) and a frame made of AISI 304/316 stainless steel.

If the product is unpackaged, always choose a non-porous belt with minimal elongation.

A speed of 0.4–1.0 m/s is typically used for packaging.

For precise packaging, it is better to reduce the speed to 0.1–0.4 m/s to ensure stable feeding.

PU belts — very low elongation (≤0.8%), resistant to oils and fats, suitable for open food products.

PVC belts — more economical and universal, used in most general industrial processes.

For a food line, PU is strongly recommended.

Causes: incorrect tension, misaligned drums, worn rollers, or moisture.

Solutions: install self-centering rollers, precision tensioners, and check drum parallelism (tolerance ±1.5 mm/m).

You need to calculate the torque on the shaft:

belt mass + product load + friction coefficient + incline angle.

IE3–IE4 motor-gear units ensure stable start-up and reduced power consumption.

For light-duty conveyors, 0.12–0.75 kW is typically sufficient.

Every 150–200 operating hours or after significant temperature changes.

PU belts require tensioning less frequently due to their minimal elongation.

Smooth belts — up to 18°

Chevron or sidewall belts — up to 30° without product slippage.

Yes — when equipped with PU non-porous belts, antistatic execution, and AISI 304/316 stainless-steel construction.

Noise level <65 dB is also a major advantage for clean-room environments.

Install STIF sensors that monitor:

– temperature,

– belt speed,

– blockages.

The system detects issues before the conveyor stops, enabling predictive maintenance.

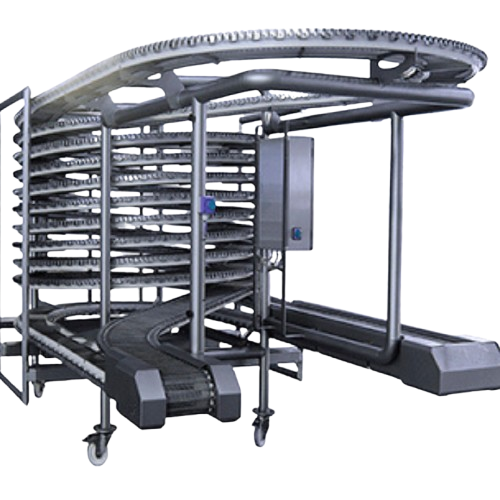

Implemented projects: Light conveyors

Our START-UP light-duty conveyors operate in food-processing, packaging, pharmaceutical, and logistics facilities across Ukraine, providing stable product flow, hygienic safety, and up to –12% energy savings thanks to lightweight PU/PVC belts and IE3–IE4 drive systems.

The intelligent monitoring system with STIF sensors controls temperature, speed, and blockages in real time, while the belt with controlled elongation ≤ 0.8% ensures smooth motion and eliminates downtime in critical packaging and inspection zones.

See for yourself — these are real projects where engineering precision becomes measurable results.

Other products

How can we help?

START-UP Conveyor Service

We find solutions where others see problems.

Contact us — an engineer will respond within 24 hours.