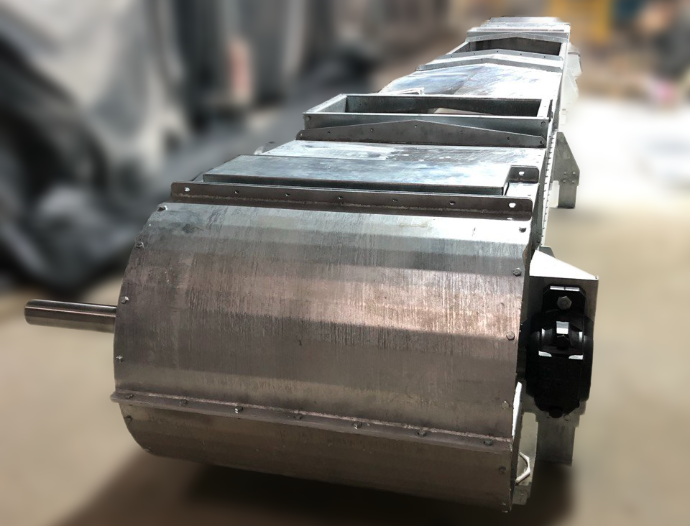

SKIF Heavy-Duty Conveyors — Reliability and Power with Zero Downtime

Heavy-duty conveyors engineered by the European company SKIF (Slovakia) are designed for continuous 24/7 operation in the most demanding environments of the agro, feed-mill, milling, metallurgical and food industries.

SKIF Heavy-Duty systems combine mechanical strength, high energy efficiency, and full readiness for SCADA/IIoT integration, delivering up to 98% uptime and reducing TCO by up to 25%.

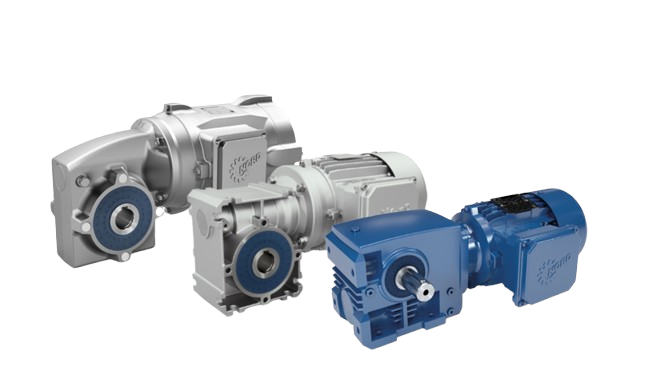

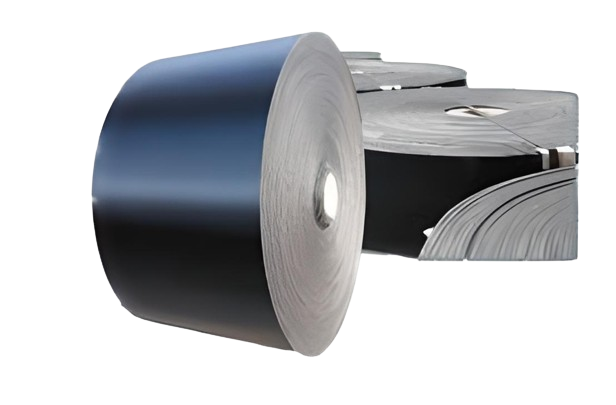

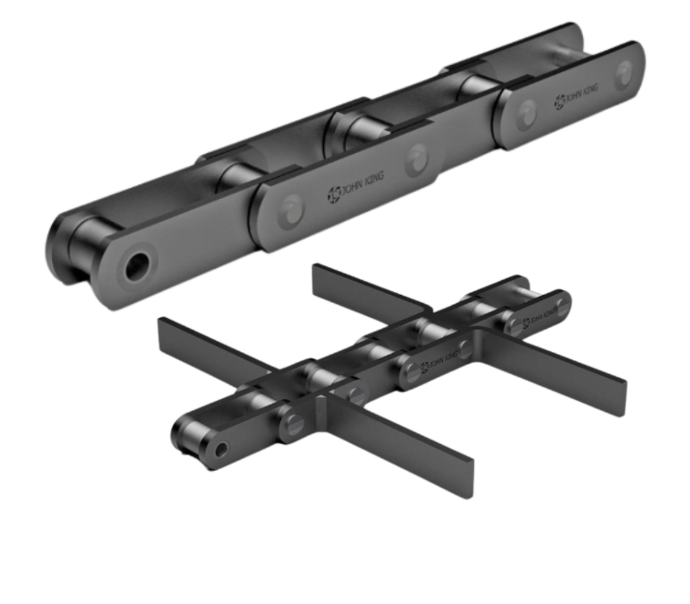

The design incorporates NORD / DODGE IE4–IE5 drives, JOHN KING chains, ARTEGO belts, and SKIF-PU wear-resistant lining, ensuring extended component life and stable performance under peak loads.

Optional STIF sensors monitor temperature, speed, misalignment, and spark detection in real time, supporting predictive maintenance and compliance with ATEX Zones 21/22.

This is a solution for companies that prioritize engineering reliability, minimal downtime, and maximum production efficiency.

Your Problems — Our Solutions

Types of Conveyor Equipment

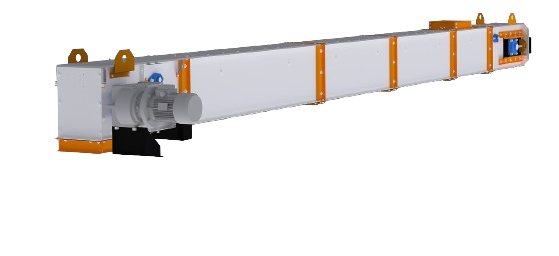

ECOFLOW

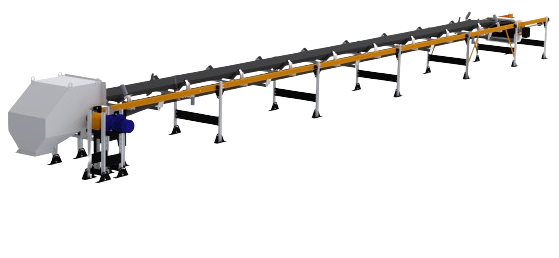

DURABELT

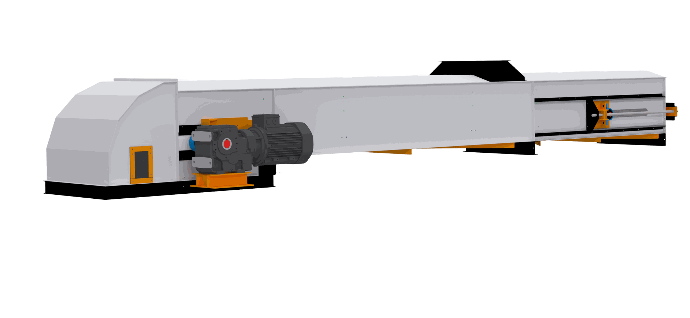

DURABELT SHUT

START-UP Light-Duty Conveyors — Stable Performance With Zero Belt Drift

START-UP light-duty conveyors are modular transport systems designed for precise and stable movement of packaged and unit products in environments where hygiene, minimal belt elongation, energy efficiency, and low noise levels are critical.

The design is based on a lightweight, high-rigidity frame and PU/PVC belts with controlled deformation parameters, ensuring accurate product flow and extended service life.

The use of UHMW-PE guides, IE3–IE4 motor-gear units, and food-grade AISI 304/316 materials provides a combination of advantages that make these conveyors ideal for the food, pharmaceutical, and packaging industries: stable belt tracking, hygiene compliance, low operating costs, and the ability to scale the line without altering the core design.

Your Problems — Our Solutions

Advantages Proven by Numbers

Stable Belt Tracking

≤ 0,8%

Reduced Energy Consumption

10–18%

Noise Level

< 65 dB

Fast Cleaning

≤ 3 min

Engineering Precision

±2 mm/m

FAQ — Questions Clients Frequently Ask

It depends entirely on your product type and conveying conditions.

-

For grain, pellets, or meal, the optimal choice is the SKIF ECOFLOW belt conveyor, which ensures gentle handling without product damage.

-

For heavy or abrasive materials, the SKIF DURABELT chain conveyor is the best fit.

-

For applications requiring airtightness and minimal dust, choose SKIF DURABELT SHUT.

Our engineers will help configure the exact system for your line.

Yes.

All SKIF conveyors have a modular design and are fully compatible with standard European-type components.

We adapt the system to your route, height, angle, and existing loading/unloading points.

When necessary, we perform digital 3D scanning of the facility before installation to calculate precise alignment.

All SKIF models are equipped with SKIF-PU anti-abrasive lining — a polyurethane liner that reduces friction and extends the life of the housing by 2–3×.

For highly aggressive environments, a combined lining SKIF-PU + HARDOX is available.

The material is resistant to impact, dust, and moisture.

With proper tensioning and precise drum alignment, an ARTEGO belt typically lasts 4–6 years, even under continuous 24/7 load.

This is 40–60% longer than standard mid-class belts.

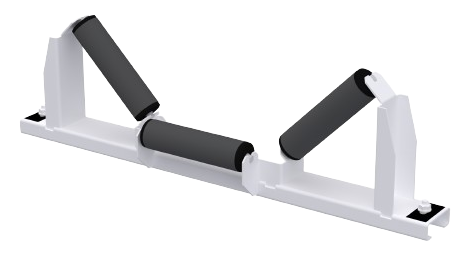

We also use low-friction idlers, which further reduce belt wear and noise.

Yes — as an option.

We use STIF (France) smart sensor systems — speed monitoring, temperature control, belt misalignment detection, and spark detection.

All components are ATEX-certified and can be integrated into SCADA or IIoT platforms.

This enables predictive maintenance, identifying issues before they develop.

Start by defining the type of product (moisture, fat content, abrasiveness), then determine the required belt width and speed.

For food-contact zones, use PU food-grade belts (HACCP / EU 1935/2004) and a frame made of AISI 304/316 stainless steel.

If the product is unpackaged, always choose a non-porous belt with minimal elongation.

A speed of 0.4–1.0 m/s is typically used for packaging.

For precise packaging, it is better to reduce the speed to 0.1–0.4 m/s to ensure stable feeding.

PU belts — very low elongation (≤0.8%), resistant to oils and fats, suitable for open food products.

PVC belts — more economical and universal, used in most general industrial processes.

For a food line, PU is strongly recommended.

Causes: incorrect tension, misaligned drums, worn rollers, or moisture.

Solutions: install self-centering rollers, precision tensioners, and check drum parallelism (tolerance ±1.5 mm/m).

Every 150–200 operating hours or after significant temperature changes.

PU belts require tensioning less frequently due to their minimal elongation.

Yes — when equipped with PU non-porous belts, antistatic execution, and AISI 304/316 stainless-steel construction.

Noise level <65 dB is also a major advantage for clean-room environments.

Формат реалізації проєкту під ключ

Інженерія

Постачання

Монтаж

Запуск і здача в експлуатацію

Completed Projects: Heavy-Duty Conveyors

Over 1,000 hours of uninterrupted operation at key industrial facilities across Ukraine.

Explore real cases where SKIF conveyors have increased productivity and reduced operating costs.

They ensure stable 24/7 performance, minimized dust emissions, and up to 25% energy savings.

Sealed housings, SKIF-PU lining, and STIF sensors guarantee reliability and safe operation of every conveying line.

Learn more

Implemented projects: Light conveyors

Our START-UP light-duty conveyors operate in food-processing, packaging, pharmaceutical, and logistics facilities across Ukraine, providing stable product flow, hygienic safety, and up to –12% energy savings thanks to lightweight PU/PVC belts and IE3–IE4 drive systems.

The intelligent monitoring system with STIF sensors controls temperature, speed, and blockages in real time, while the belt with controlled elongation ≤ 0.8% ensures smooth motion and eliminates downtime in critical packaging and inspection zones.

See for yourself — these are real projects where engineering precision becomes measurable results.