VIGILEX & STUVEX — The Benchmark of European Industrial Safety

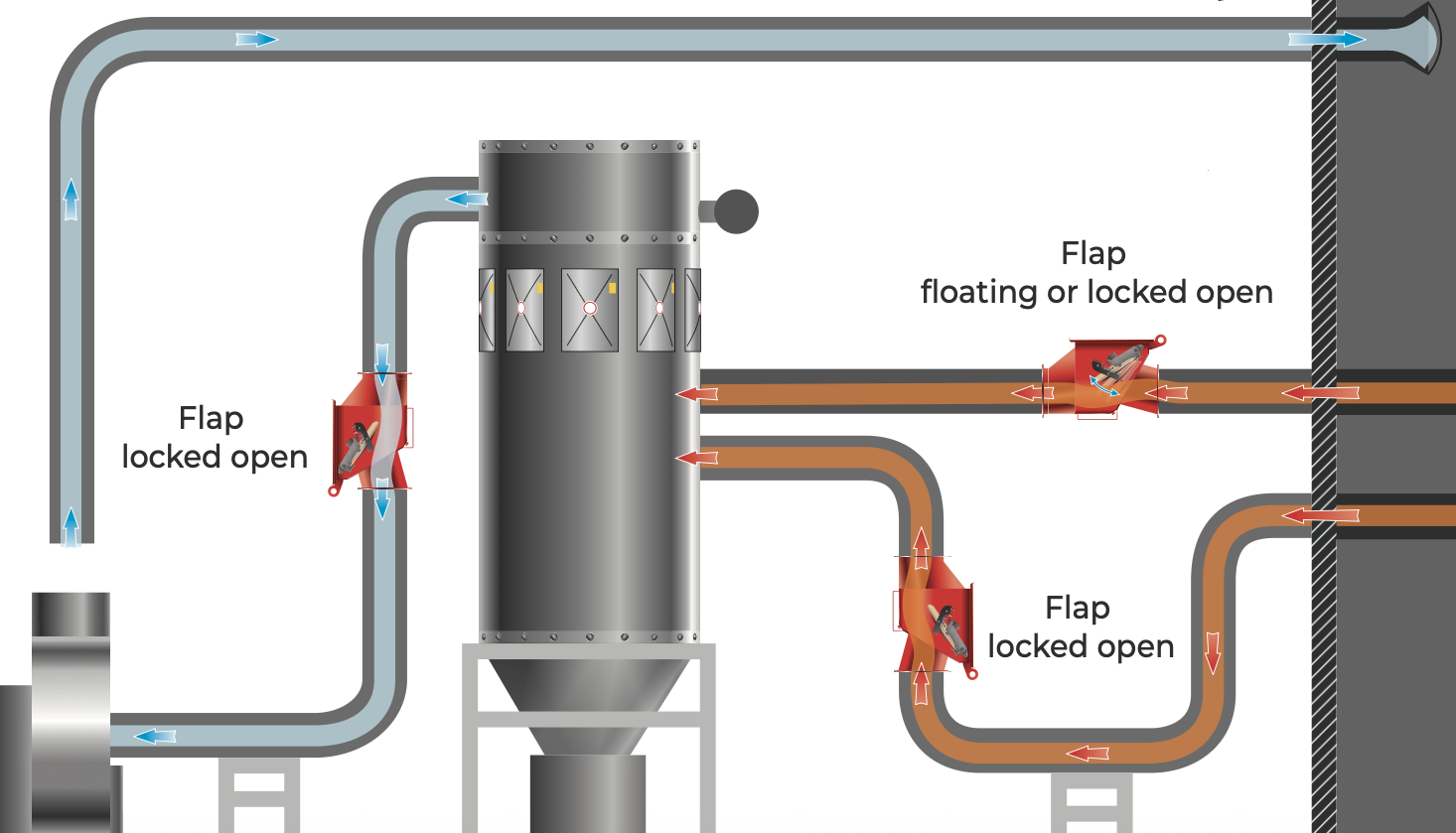

The intelligent safety systems from VIGILEX (France) and STUVEX (Belgium) are high-precision European solutions designed for continuous monitoring of critical zones in bulk-material conveying. They operate 24/7, react to hazardous deviations in milliseconds, and comply with the highest ATEX safety requirements.

VIGILEX explosion panels instantly relieve overpressure during a dust explosion, preventing equipment destruction — a reliable passive protection method widely used in European grain elevators for decades.

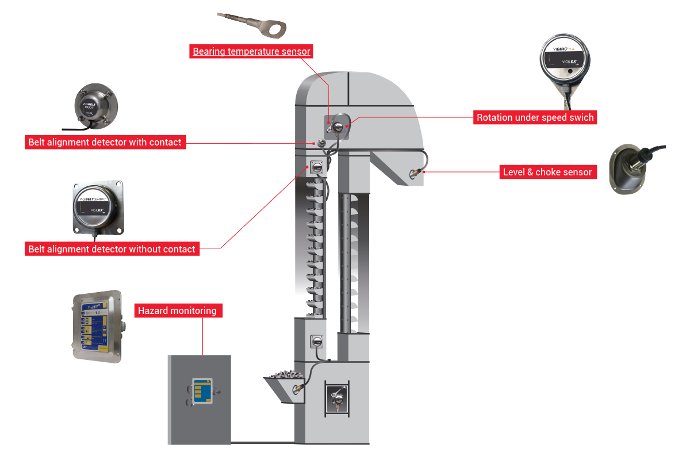

The monitoring sensors detect belt speed, misalignment, temperature, and blockage. When abnormal conditions occur, the system triggers an alarm in the PLC and stops the drive, preventing failure or fire.

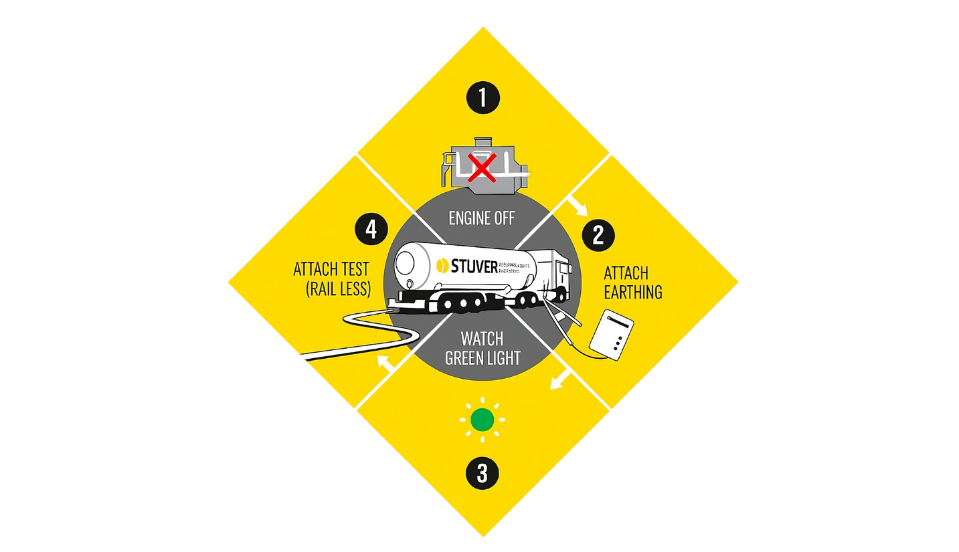

Safe-Ground systems monitor grounding of equipment, Big-Bags, and trucks — fully eliminating static charge that may generate a spark.

PSD3-D detectors identify sparks and overheated particles within 1 ms in pneumatic lines and dryers, triggering extinguishing or emergency shutdown to prevent dust explosions.

Your Problems — Our Solutions

Types of Industrial Safety Systems

Explosion Protection

Monitoring Systems

Electrostatic Protection

FAQ — Questions Clients Frequently Ask

You first need to identify the specific risks: belt speed, belt misalignment, bearing temperature, or blockage.

VIGILEX offers a dedicated sensor for each risk, and all sensors can be combined into a single integrated system.

Yes.

Monitoring eliminates the root causes of explosions: overheating, belt slip, misalignment, and material blockage.

This allows the drive to be stopped before ignition or critical friction occurs inside the bucket elevator.

They instantly relieve excess pressure during a dust explosion inside equipment, preventing the casing from rupturing.

This is a fundamental element of passive explosion protection for elevators and silo systems.

VIGILEX relieves pressure after the explosion has started.

STUVEX works before the explosion — detecting sparks, monitoring static electricity, and triggering emergency shutdown to prevent the explosion from occurring.

Yes.

PSD3-D detectors capture sparks or hot particles within 1 ms, even in darkness, high airflow, and heavy dust loads.

Yes, they are fully compatible.

VIGILEX monitors mechanical parameters, while STUVEX detects static electricity and sparks.

Together, they create a complete safety loop for elevators and conveyors.

Systems S604 / S804 / TES01-V2 display grounding status (green/red) and block operation until proper grounding is confirmed.

Install the VIGIMAT sensor.

It detects critical material levels in the elevator boot and shuts down the system before deformation or overheating occurs.

Minimal.

Once per season, check sensor mounts, clean optical lenses (for STUVEX), and verify electrical contacts.

Yes.

The MGS01-V1 system monitors up to 10 grounding points at the same time, each with its own control module.

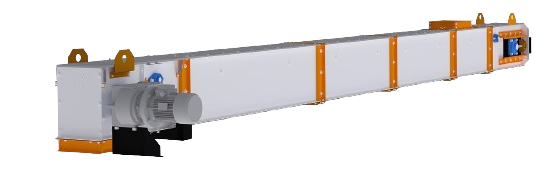

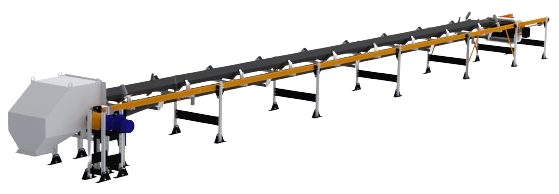

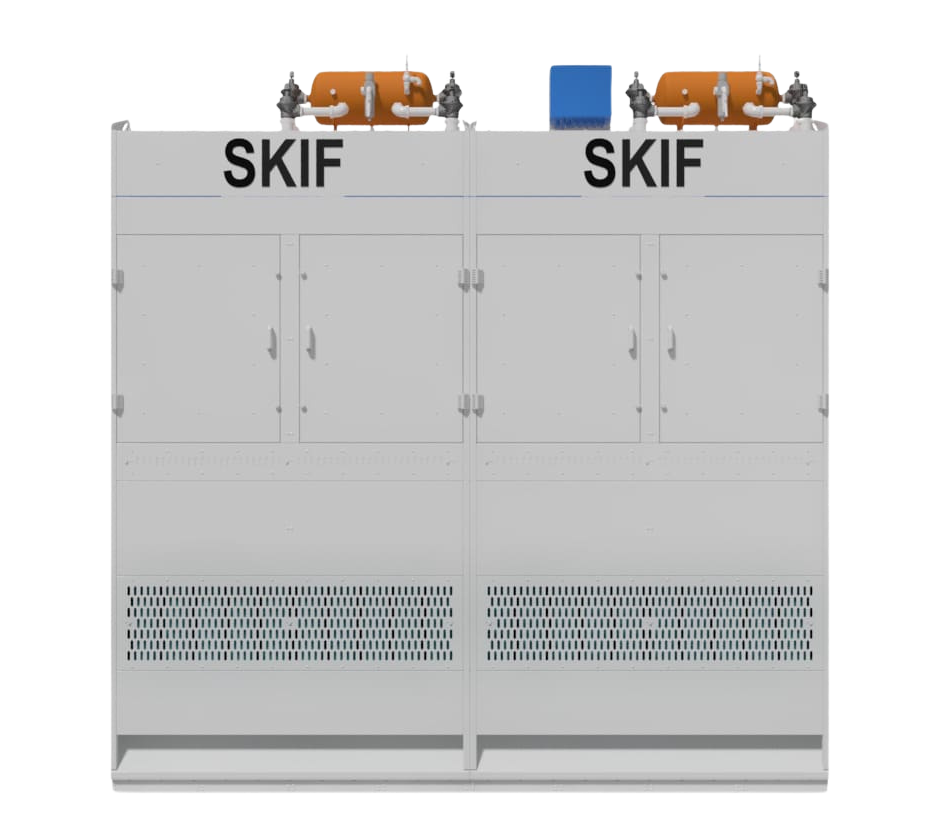

Other products

Contact Our Specialist

Aspiration & Explosion Safety

Artem Morozov

Since 2017, I have been working with solutions for agro-industrial, feed-mill, and milling facilities — from dust-generation audits to the implementation of aspiration and explosion-protection systems.

At START-UP, I am responsible for equipment selection, system design, STIF technologies, and full project support.

My approach is based on ATEX, CE, and ISO compliance, engineering precision, and predictable system performance.