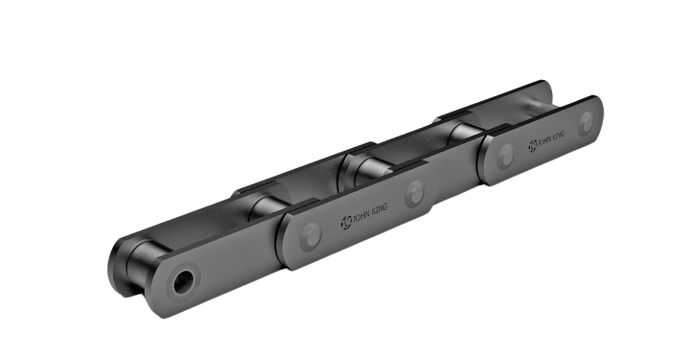

American standard engineering chains

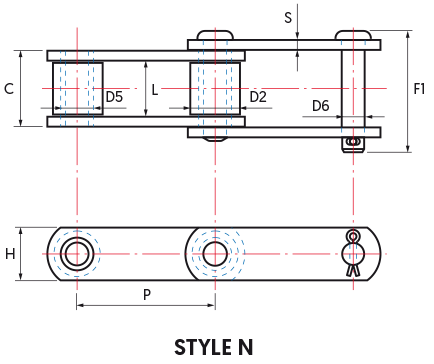

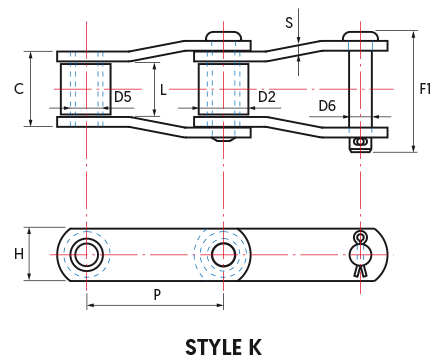

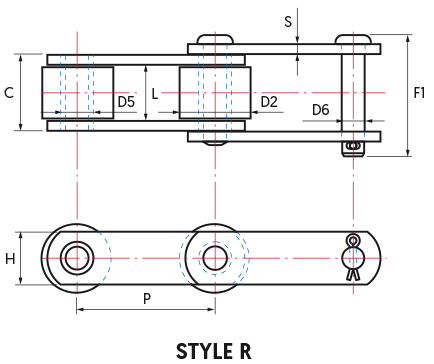

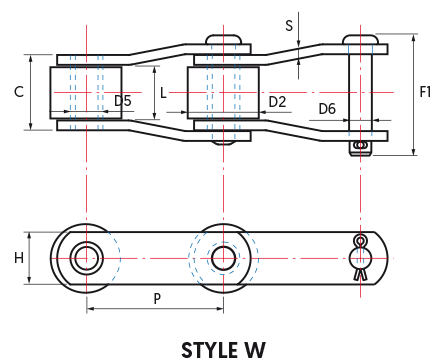

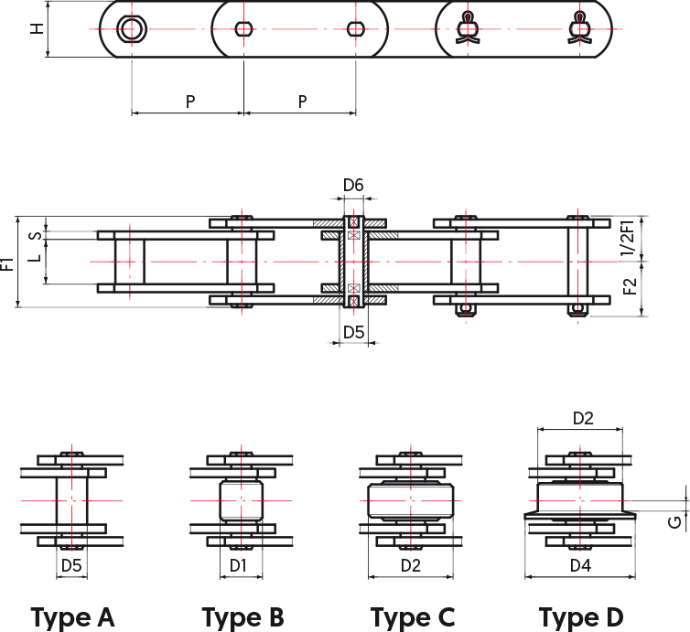

| American Standard Engineered Steel Chains with Rollers | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain Number |

Style | Pitch | Rollers | Bushings | Pins | Over-All Pin & Cotter |

Between Sidebars |

Sidebars | Minimum Breaking Load |

Average Weight |

||||||

| Outside Diameter | G | Heat Treat |

Outside Diameter | Diameter | Heat Treat |

Thickness | Height | Heat Treat |

||||||||

| P | D2 | D5 | D6 | F1 | L | S | H | |||||||||

| inches | inches | inches | lbs | lbs/ft | ||||||||||||

| JKR81X | N | 2.609 | 0.88 | - | TH | 0.63 | 0.43 | CH | 2.14 | 1.07 | 0.16 | 1.13 | TH | 16,000 | 2.50 | |

| JKR81XH | N | 2.609 | 0.88 | - | TH | 0.63 | 0.43 | TH | 2.58 | 1.07 | 0.31 | 1.27 | TH | 28,000 | 4.10 | |

| JKR81XHH | N | 2.609 | 0.88 | - | TH | 0.63 | 0.43 | TH | 2.76 | 1.07 | 0.31 | 1.27 | TH | 28,000 | 4.60 | |

| JKR1539 | K | 3.075 | 1.25 | - | TH | 0.89 | 0.63 | CH | 3.50 | 1.50 | 0.31 | 1.50 | TH | 24,000 | 6.80 | |

| JKR0904 | R | 4.000 | 2.00 | - | CH | 1.00 | 0.69 | TH | 3.13 | 1.22 | 0.31 | 1.75 | TH | 40,000 | 10.80 | |

| JKR1120 | N | 4.000 | 1.50 | - | CH | 0.63 | 0.44 | TH | 2.28 | 1.00 | 0.19 | 1.13 | TH | 13,000 | 3.40 | |

| JKR188 | N | 4.000 | 1.75 | - | CH | 0.63 | 0.44 | CH | 2.47 | 1.19 | 0.19 | 1.13 | TH | 13,000 | 4.20 | |

| JKR2188 | N | 4.000 | 1.75 | - | CH | 0.94 | 0.63 | CH | 3.25 | 1.31 | 0.31 | 1.50 | TH | 23,000 | 7.00 | |

| JKR2102 | N | 4.000 | 1.50 | - | CH | 1.00 | 0.62 | CIH | 4.53 | 2.22 | 0.37 | 1.50 | TH | 56,500 | 9.00 | |

| JKR2868 | N | 4.000 | 1.44 | - | CH | 1.06 | 0.75 | CIH | 4.36 | 2.00 | 0.38 | 1.75 | TH | 56,500 | 12.10 | |

| JKR3952 | N | 4.000 | 1.43 | - | CH | 1.00 | 0.75 | CIH | 4.125 | 2.00 | 0.37 | 1.75 | TH | 62,000 | 12.10 | |

| JKR3945 | N | 4.000 | 1.25 | - | CH | 1.00 | 0.62 | CIH | 4.00 | 2.00 | 0.31 | 1.50 | TH | 45,000 | 9.50 | |

| JKR2848 | R | 4.040 | 1.50 | - | TH | 1.00 | 0.69 | CIH | 4.26 | 2.00 | 0.38 | 2.00 | TH | 48,000 | 11.00 | |

| JKR3420 | R | 4.040 | 2.00 | - | CH | 0.94 | 0.63 | CH | 3.25 | 1.31 | 0.31 | 1.50 | TH | 23,000 | 7.60 | |

| JKR2268 | N | 4.083 | 1.62 | - | CH | 1.13 | 0.75 | CIH | 4.125 | 2.00 | 0.37 | 2.25 | TH | 100,000 | 13.00 | |

| JKR3950 | N | 4.038 | 1.37 | - | CH | 1.00 | 0.62 | CIH | 3.086 | 2.00 | 0.31 | 1.50 | TH | 45,000 | 9.40 | |

| JKR2858 | N | 4.083 | 1.63 | - | CH | 1.13 | 0.75 | CIH | 4.37 | 2.00 | 0.38 | 2.25 | TH | 57,000 | 13.00 | |

| JKR3285 | N | 4.500 | 2.00 | - | TH | 1.31 | 0.94 | CIH | 4.94 | 2.06 | 0.50 | 2.50 | TH | 91,000 | 21.00 | |

| JKR4604 | N | 4.604 | 1.37 | - | CH | 1.31 | 0.625 | CIH | 4.38 | 2.00 | 0.31 | 1.50 | TH | 45,000 | 12.64 | |

| JKR196 | R | 6.00 | 2.00 | 1.09 | CH | 0.63 | 0.44 | CH | 2.72 | 1.19 | 0.25 | 1.50 | TH | 18,000 | 5.00 | |

| JKR0196 | R | 6.00 | 2.00 | 1.19 | CH | 0.81 | 0.56 | CH | 2.89 | 1.25 | 0.25 | 1.50 | TH | 21,000 | 5.00 | |

| JKR2190 | R | 6.00 | 2.50 | 1.19 | CH | 0.81 | 0.56 | CH | 2.89 | 1.25 | 0.25 | 1.50 | TH | 21,000 | 7.00 | |

| JKR1114 | R | 6.00 | 2.00 | 1.25 | CH | 0.94 | 0.63 | CH | 3.25 | 1.31 | 0.31 | 1.50 | TH | 23,000 | 6.30 | |

| JKR2183 | R | 6.00 | 3.00 | 1.38 | CH | 0.89 | 0.63 | CH | 3.50 | 1.50 | 0.31 | 1.50 | TH | 24,000 | 10.70 | |

| JKR3130 | W | 6.00 | 2.50 | 0.94 | CH | 1.13 | 0.75 | CH | 3.53 | 1.25 | 0.38 | 2.00 | TH | 45,000 | 10.00 | |

| JKR2111 | N | 6.00 | 3.00 | 1.50 | CH | 1.25 | 0.88 | TH | 3.84 | 1.56 | 0.38 | 2.00 | TH | 67,000 | 9.60 | |

| JKR2124 | R | 6.00 | 2.75 | 1.44 | CH | 1.13 | 0.75 | TH | 3.84 | 1.56 | 0.38 | 2.00 | TH | 63,000 | 11.80 | |

| JKR1131 | R | 6.00 | 3.00 | 1.38 | CH | 1.13 | 0.75 | TH | 3.84 | 1.56 | 0.38 | 2.00 | TH | 45,000 | 12.50 | |

| JKR2184 | W | 6.00 | 3.00 | 1.06 | CH | 1.25 | 0.88 | CIH | 3.76 | 1.38 | 0.38 | 2.00 | TH | 58,000 | 12.30 | |

| JKR9184 | W | 6.00 | 3.00 | 1.20 | CH | 1.38 | 0.94 | CIH | 4.41 | 1.56 | 0.50 | 2.50 | TH | 100,000 | 15.20 | |

| JKR2198 | W | 6.00 | 2.75 | 1.25 | CH | 1.30 | 0.88 | CIH | 4.43 | 1.56 | 0.50 | 2.25 | TH | 64,000 | 18.20 | |

| American Standard Engineered Steel Chains with Rollers | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain Number |

Style | Pitch | Rollers | Bushings | Pins | Over-All Pin & Cotter |

Between Sidebars |

Sidebars | Minimum Breaking Load |

Average Weight |

||||||

| Outside Diameter | G | Heat Treat |

Outside Diameter | Diameter | Heat Treat |

Thickness | Height | Heat Treat |

||||||||

| P | D2 | D5 | D6 | F1 | L | S | H | |||||||||

| inches | inches | inches | lbs | lbs/ft | ||||||||||||

| JKR81X | N | 2.609 | 0.88 | - | TH | 0.63 | 0.43 | CH | 2.14 | 1.07 | 0.16 | 1.13 | TH | 16,000 | 2.50 | |

| JKR81XH | N | 2.609 | 0.88 | - | TH | 0.63 | 0.43 | TH | 2.58 | 1.07 | 0.31 | 1.27 | TH | 28,000 | 4.10 | |

| JKR81XHH | N | 2.609 | 0.88 | - | TH | 0.63 | 0.43 | TH | 2.76 | 1.07 | 0.31 | 1.27 | TH | 28,000 | 4.60 | |

| JKR1539 | K | 3.075 | 1.25 | - | TH | 0.89 | 0.63 | CH | 3.50 | 1.50 | 0.31 | 1.50 | TH | 24,000 | 6.80 | |

| JKR0904 | R | 4.000 | 2.00 | - | CH | 1.00 | 0.69 | TH | 3.13 | 1.22 | 0.31 | 1.75 | TH | 40,000 | 10.80 | |

| JKR1120 | N | 4.000 | 1.50 | - | CH | 0.63 | 0.44 | TH | 2.28 | 1.00 | 0.19 | 1.13 | TH | 13,000 | 3.40 | |

| JKR188 | N | 4.000 | 1.75 | - | CH | 0.63 | 0.44 | CH | 2.47 | 1.19 | 0.19 | 1.13 | TH | 13,000 | 4.20 | |

| JKR2188 | N | 4.000 | 1.75 | - | CH | 0.94 | 0.63 | CH | 3.25 | 1.31 | 0.31 | 1.50 | TH | 23,000 | 7.00 | |

| JKR2102 | N | 4.000 | 1.50 | - | CH | 1.00 | 0.62 | CIH | 4.53 | 2.22 | 0.37 | 1.50 | TH | 56,500 | 9.00 | |

| JKR2868 | N | 4.000 | 1.44 | - | CH | 1.06 | 0.75 | CIH | 4.36 | 2.00 | 0.38 | 1.75 | TH | 56,500 | 12.10 | |

| JKR3952 | N | 4.000 | 1.43 | - | CH | 1.00 | 0.75 | CIH | 4.125 | 2.00 | 0.37 | 1.75 | TH | 62,000 | 12.10 | |

| JKR3945 | N | 4.000 | 1.25 | - | CH | 1.00 | 0.62 | CIH | 4.00 | 2.00 | 0.31 | 1.50 | TH | 45,000 | 9.50 | |

| JKR2848 | R | 4.040 | 1.50 | - | TH | 1.00 | 0.69 | CIH | 4.26 | 2.00 | 0.38 | 2.00 | TH | 48,000 | 11.00 | |

| JKR3420 | R | 4.040 | 2.00 | - | CH | 0.94 | 0.63 | CH | 3.25 | 1.31 | 0.31 | 1.50 | TH | 23,000 | 7.60 | |

| JKR2268 | N | 4.083 | 1.62 | - | CH | 1.13 | 0.75 | CIH | 4.125 | 2.00 | 0.37 | 2.25 | TH | 100,000 | 13.00 | |

| JKR3950 | N | 4.038 | 1.37 | - | CH | 1.00 | 0.62 | CIH | 3.086 | 2.00 | 0.31 | 1.50 | TH | 45,000 | 9.40 | |

| JKR2858 | N | 4.083 | 1.63 | - | CH | 1.13 | 0.75 | CIH | 4.37 | 2.00 | 0.38 | 2.25 | TH | 57,000 | 13.00 | |

| JKR3285 | N | 4.500 | 2.00 | - | TH | 1.31 | 0.94 | CIH | 4.94 | 2.06 | 0.50 | 2.50 | TH | 91,000 | 21.00 | |

| JKR4604 | N | 4.604 | 1.37 | - | CH | 1.31 | 0.625 | CIH | 4.38 | 2.00 | 0.31 | 1.50 | TH | 45,000 | 12.64 | |

| JKR196 | R | 6.00 | 2.00 | 1.09 | CH | 0.63 | 0.44 | CH | 2.72 | 1.19 | 0.25 | 1.50 | TH | 18,000 | 5.00 | |

| JKR0196 | R | 6.00 | 2.00 | 1.19 | CH | 0.81 | 0.56 | CH | 2.89 | 1.25 | 0.25 | 1.50 | TH | 21,000 | 5.00 | |

| JKR2190 | R | 6.00 | 2.50 | 1.19 | CH | 0.81 | 0.56 | CH | 2.89 | 1.25 | 0.25 | 1.50 | TH | 21,000 | 7.00 | |

| JKR1114 | R | 6.00 | 2.00 | 1.25 | CH | 0.94 | 0.63 | CH | 3.25 | 1.31 | 0.31 | 1.50 | TH | 23,000 | 6.30 | |

| JKR2183 | R | 6.00 | 3.00 | 1.38 | CH | 0.89 | 0.63 | CH | 3.50 | 1.50 | 0.31 | 1.50 | TH | 24,000 | 10.70 | |

| JKR3130 | W | 6.00 | 2.50 | 0.94 | CH | 1.13 | 0.75 | CH | 3.53 | 1.25 | 0.38 | 2.00 | TH | 45,000 | 10.00 | |

| JKR2111 | N | 6.00 | 3.00 | 1.50 | CH | 1.25 | 0.88 | TH | 3.84 | 1.56 | 0.38 | 2.00 | TH | 67,000 | 9.60 | |

| JKR2124 | R | 6.00 | 2.75 | 1.44 | CH | 1.13 | 0.75 | TH | 3.84 | 1.56 | 0.38 | 2.00 | TH | 63,000 | 11.80 | |

| JKR1131 | R | 6.00 | 3.00 | 1.38 | CH | 1.13 | 0.75 | TH | 3.84 | 1.56 | 0.38 | 2.00 | TH | 45,000 | 12.50 | |

| JKR2184 | W | 6.00 | 3.00 | 1.06 | CH | 1.25 | 0.88 | CIH | 3.76 | 1.38 | 0.38 | 2.00 | TH | 58,000 | 12.30 | |

| JKR9184 | W | 6.00 | 3.00 | 1.20 | CH | 1.38 | 0.94 | CIH | 4.41 | 1.56 | 0.50 | 2.50 | TH | 100,000 | 15.20 | |

| JKR2198 | W | 6.00 | 2.75 | 1.25 | CH | 1.30 | 0.88 | CIH | 4.43 | 1.56 | 0.50 | 2.25 | TH | 64,000 | 18.20 | |

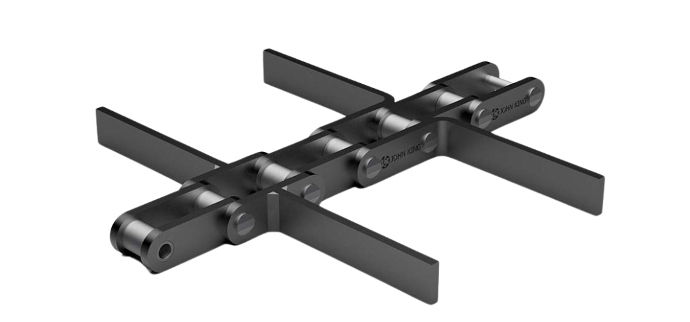

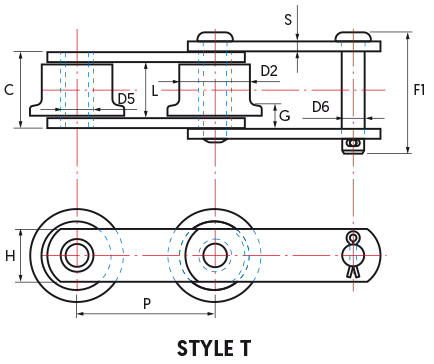

Carrier chain

| Carrier chain | ||||||||

|---|---|---|---|---|---|---|---|---|

| Chain Number |

Units | C1 | C2 | C | E | E1 | D | T |

| JKB37291 | mm | 18.40 | 146.30 | 93.70 | 57.20 | 44.50 | 35.80 | 12.70 |

| in | 7.26 | 5.76 | 3.69 | 2.25 | 1.75 | 1.41 | 0.50 | |

| Carrier chain | ||||||||

|---|---|---|---|---|---|---|---|---|

| Chain Number |

Units | C1 | C2 | C | E | E1 | D | T |

| JKB37291 | mm | 18.40 | 146.30 | 93.70 | 57.20 | 44.50 | 35.80 | 12.70 |

| in | 7.26 | 5.76 | 3.69 | 2.25 | 1.75 | 1.41 | 0.50 | |

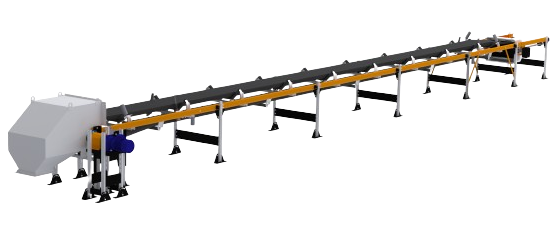

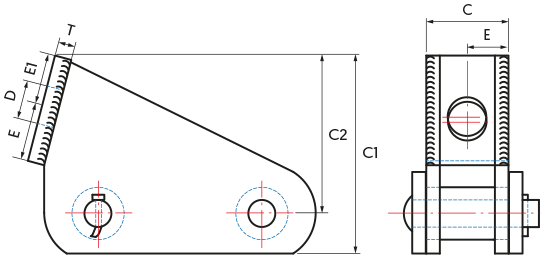

Bagasse conveyor chain

| Cobra style Chain for Main Cane and Auxilliary Carrier Conveyors | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain Number |

Units | Pitch | Rollers | Bushings | Pins | Over-All Pin & Cotter |

Between Sidebars |

Sidebars | Square Hole | Working Load | Breaking Load | Weight | ||||

| Diameter | Thickness | Height | ||||||||||||||

| P | D2 | D5 | D6 | F | L | S | H | M14 | ||||||||

| JKR2397 | mm | 304.80 | 44.45 | 31.75 | 22.40 | 119.85 | 55.60 | 9.52 | 63.50 | 19.05 | 4,200 kg | 40,900 kg | 14.16 kg/m | |||

| in | 12.00 | 1.75 | 1.25 | 0.88 | 4.71 | 2.18 | 0.38 | 2.50 | 0.75 | 9,420 ib | 90,000 ib | 9.79 ib/ft | ||||

| JKR2358 | mm | 228.660 | 44.60 | 31.75 | 22.40 | 123.95 | 49.30 | 12.70 | 63.50 | 25.40 | 4,091 kg | 45,455 kg | 15.20 kg/m | |||

| in | 9.00 | 1.75 | 1.25 | 0.88 | 4.88 | 1.94 | 0.50 | 2.50 | 1.00 | 14,000 ib | 100,000 ib | 10.20 ib/ft | ||||

| JKR1706 | mm | 304.80 | 57.20 | 38.10 | 25.40 | 148.30 | 76.20 | 12.70 | 63.50 | 25.40 | 6,364 kg | 45,455 kg | 6.00 kg/m | |||

| in | 9.00 | 1.75 | 1.25 | 0.88 | 4.88 | 1.94 | 0.50 | 2.50 | 1.00 | 14,000 ib | 100,000 ib | 10.20 ib/ft | ||||

| JKR2648 | mm | 304.80 | 82.55 | 55.62 | 41.28 | 197.60 | 92.08 | 19.05 | 101.60 | 31.80 | 13,454 kg | 159,090 kg | 53.52 kg/m | |||

| in | 12.00 | 3.25 | 2.19 | 1.62 | 7.78 | 3.62 | 0.75 | 4.00 | 1.25 | 30,000 ib | 350,000 ib | 35.90 ib/ft | ||||

| Cobra style Chain for Main Cane and Auxilliary Carrier Conveyors | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain Number |

Units | Pitch | Rollers | Bushings | Pins | Over-All Pin & Cotter |

Between Sidebars |

Sidebars | Square Hole | Working Load | Breaking Load | Weight | ||||

| Diameter | Thickness | Height | ||||||||||||||

| P | D2 | D5 | D6 | F | L | S | H | M14 | ||||||||

| JKR2397 | mm | 304.80 | 44.45 | 31.75 | 22.40 | 119.85 | 55.60 | 9.52 | 63.50 | 19.05 | 4,200 kg | 40,900 kg | 14.16 kg/m | |||

| in | 12.00 | 1.75 | 1.25 | 0.88 | 4.71 | 2.18 | 0.38 | 2.50 | 0.75 | 9,420 ib | 90,000 ib | 9.79 ib/ft | ||||

| JKR2358 | mm | 228.660 | 44.60 | 31.75 | 22.40 | 123.95 | 49.30 | 12.70 | 63.50 | 25.40 | 4,091 kg | 45,455 kg | 15.20 kg/m | |||

| in | 9.00 | 1.75 | 1.25 | 0.88 | 4.88 | 1.94 | 0.50 | 2.50 | 1.00 | 14,000 ib | 100,000 ib | 10.20 ib/ft | ||||

| JKR1706 | mm | 304.80 | 57.20 | 38.10 | 25.40 | 148.30 | 76.20 | 12.70 | 63.50 | 25.40 | 6,364 kg | 45,455 kg | 6.00 kg/m | |||

| in | 9.00 | 1.75 | 1.25 | 0.88 | 4.88 | 1.94 | 0.50 | 2.50 | 1.00 | 14,000 ib | 100,000 ib | 10.20 ib/ft | ||||

| JKR2648 | mm | 304.80 | 82.55 | 55.62 | 41.28 | 197.60 | 92.08 | 19.05 | 101.60 | 31.80 | 13,454 kg | 159,090 kg | 53.52 kg/m | |||

| in | 12.00 | 3.25 | 2.19 | 1.62 | 7.78 | 3.62 | 0.75 | 4.00 | 1.25 | 30,000 ib | 350,000 ib | 35.90 ib/ft | ||||

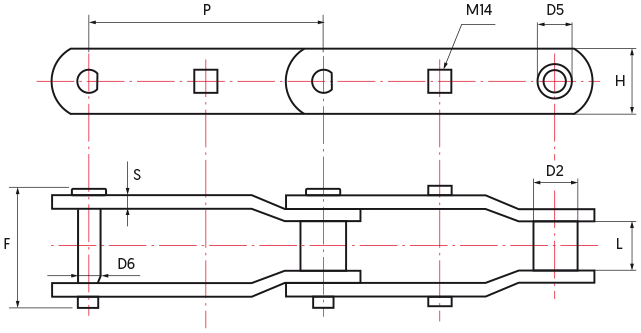

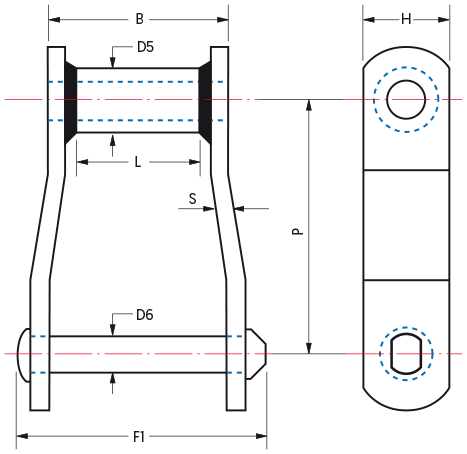

Steel bush chain

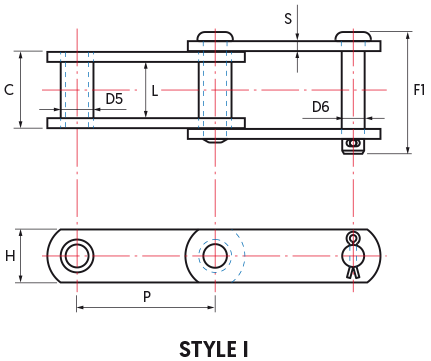

| American Standard Engineered Steel without Rollers | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain Number |

Style | Pitch | Bushings | Pins | Over-All Pin & Cotter |

Between Sidebars |

Sidebars | Minimum Breaking Load |

Average Weight |

||||||

| Outside Diameter | Width | Heat Treat |

Diameter | Heat Treat |

Thickness | Height | Heat Treat |

||||||||

| P | D5 | C | D6 | F1 | L | S | H | ||||||||

| inches | inches | inches | lbs | lbs/ft | |||||||||||

| SS188 | I | 2.069 | 0.88 | 1.57 | CH | 0.50 | CH | 2.69 | 1.06 | 0.25 | 1.13 | TH | 23,000 | 3.80 | |

| SS131 | I | 3.075 | 1.25 | 2.06 | CH | 0.63 | CH | 3.52 | 1.31 | 0.38 | 1.50 | TH | 36,000 | 7.40 | |

| SS825 | V | 4.000 | 1.14 | 2.31 | CH | 0.75 | CH | 3.87 | 1.56 | 0.38 | 2.00 | TH | 55,000 | 8.70 | |

| SS102B | I | 4.000 | 1.00 | 2.89 | CH | 0.63 | CH | 4.37 | 2.13 | 0.38 | 1.50 | TH | 36,000 | 6.90 | |

| SS102.5 | I | 4.040 | 1.38 | 3.01 | CH | 0.75 | CH | 4.56 | 2.25 | 0.38 | 1.75 | TH | 48,000 | 9.40 | |

| JKB111 | I | 4.760 | 1.44 | 3.39 | CH | 0.75 | CIH | 4.97 | 2.63 | 0.38 | 2.00 | TH | 48,000 | 10.20 | |

| JKB110 | I | 6.000 | 1.25 | 2.89 | CH | 0.63 | CIH | 4.37 | 2.13 | 0.38 | 1.50 | TH | 36,000 | 6.30 | |

| JKB833 | I | 6.000 | 1.44 | 3.38 | CH | 0.75 | CIH | 4.97 | 2.63 | 0.38 | 2.00 | TH | 48,000 | 9.30 | |

| JKB844 | V | 6.000 | 1.19 | 3.50 | CH | 0.75 | CIH | 5.31 | 2.50 | 0.50 | 2.00 | TH | 52,000 | 10.40 | |

| JKB856 | I | 6.000 | 1.75 | 4.00 | CH | 1.00 | CIH | 5.99 | 3.00 | 0.50 | 2.50 | TH | 82,000 | 16.50 | |

| JKB956 | I | 6.000 | 1.75 | 4.00 | CH | 1.00 | CIH | 5.99 | 2.95 | 0.50 | 3.00 | TH | 97,000 | 16.60 | |

| JKB857 | I | 6.000 | 1.75 | 4.00 | CH | 1.00 | CIH | 5.99 | 3.00 | 0.50 | 3.25 | TH | 97,000 | 21.00 | |

| JKB958 | I | 6.000 | 2.00 | 4.13 | CH | 1.13 | CIH | 6.07 | 3.00 | 0.56 | 3.25 | TH | 97,000 | 21.00 | |

| JKB859 | I | 6.000 | 2.38 | 5.00 | CH | 1.25 | CIH | 7.62 | 3.75 | 0.63 | 4.00 | TH | 155,000 | 34.00 | |

| JKB6150 | I | 6.050 | 1.75 | 4.35 | CH | 1.00 | CH | 6.36 | 3.34 | 0.50 | 2.50 | TH | 124,000 | 17.20 | |

| JKB864 | I | 6.050 | 2.38 | 5.00 | CH | 1.25 | CIH | 7.62 | 3.75 | 0.63 | 4.00 | TH | 155,000 | 33.00 | |

| JKB984 | I | 7.000 | 2.50 | 5.00 | CH | 1.38 | CIH | 7.35 | 3.75 | 0.62 | 4.00 | TH | 155,000 | 33.00 | |

| JKB886 | V | 7.000 | 2.63 | 4.25 | CH | 1.63 | CIH | 6.79 | 2.75 | 0.75 | 4.00 | TH | 255,000 | 42.00 | |

| JKB4671 | I | 9.000 | 1.75 | 4.35 | CH | 1.00 | CIH | 6.21 | 3.38 | 0.50 | 3.00 | TH | 91,000 | 14.60 | |

| American Standard Engineered Steel without Rollers | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain Number |

Style | Pitch | Bushings | Pins | Over-All Pin & Cotter |

Between Sidebars |

Sidebars | Minimum Breaking Load |

Average Weight |

||||||

| Outside Diameter | Width | Heat Treat |

Diameter | Heat Treat |

Thickness | Height | Heat Treat |

||||||||

| P | D5 | C | D6 | F1 | L | S | H | ||||||||

| inches | inches | inches | lbs | lbs/ft | |||||||||||

| SS188 | I | 2.069 | 0.88 | 1.57 | CH | 0.50 | CH | 2.69 | 1.06 | 0.25 | 1.13 | TH | 23,000 | 3.80 | |

| SS131 | I | 3.075 | 1.25 | 2.06 | CH | 0.63 | CH | 3.52 | 1.31 | 0.38 | 1.50 | TH | 36,000 | 7.40 | |

| SS825 | V | 4.000 | 1.14 | 2.31 | CH | 0.75 | CH | 3.87 | 1.56 | 0.38 | 2.00 | TH | 55,000 | 8.70 | |

| SS102B | I | 4.000 | 1.00 | 2.89 | CH | 0.63 | CH | 4.37 | 2.13 | 0.38 | 1.50 | TH | 36,000 | 6.90 | |

| SS102.5 | I | 4.040 | 1.38 | 3.01 | CH | 0.75 | CH | 4.56 | 2.25 | 0.38 | 1.75 | TH | 48,000 | 9.40 | |

| JKB111 | I | 4.760 | 1.44 | 3.39 | CH | 0.75 | CIH | 4.97 | 2.63 | 0.38 | 2.00 | TH | 48,000 | 10.20 | |

| JKB110 | I | 6.000 | 1.25 | 2.89 | CH | 0.63 | CIH | 4.37 | 2.13 | 0.38 | 1.50 | TH | 36,000 | 6.30 | |

| JKB833 | I | 6.000 | 1.44 | 3.38 | CH | 0.75 | CIH | 4.97 | 2.63 | 0.38 | 2.00 | TH | 48,000 | 9.30 | |

| JKB844 | V | 6.000 | 1.19 | 3.50 | CH | 0.75 | CIH | 5.31 | 2.50 | 0.50 | 2.00 | TH | 52,000 | 10.40 | |

| JKB856 | I | 6.000 | 1.75 | 4.00 | CH | 1.00 | CIH | 5.99 | 3.00 | 0.50 | 2.50 | TH | 82,000 | 16.50 | |

| JKB956 | I | 6.000 | 1.75 | 4.00 | CH | 1.00 | CIH | 5.99 | 2.95 | 0.50 | 3.00 | TH | 97,000 | 16.60 | |

| JKB857 | I | 6.000 | 1.75 | 4.00 | CH | 1.00 | CIH | 5.99 | 3.00 | 0.50 | 3.25 | TH | 97,000 | 21.00 | |

| JKB958 | I | 6.000 | 2.00 | 4.13 | CH | 1.13 | CIH | 6.07 | 3.00 | 0.56 | 3.25 | TH | 97,000 | 21.00 | |

| JKB859 | I | 6.000 | 2.38 | 5.00 | CH | 1.25 | CIH | 7.62 | 3.75 | 0.63 | 4.00 | TH | 155,000 | 34.00 | |

| JKB6150 | I | 6.050 | 1.75 | 4.35 | CH | 1.00 | CH | 6.36 | 3.34 | 0.50 | 2.50 | TH | 124,000 | 17.20 | |

| JKB864 | I | 6.050 | 2.38 | 5.00 | CH | 1.25 | CIH | 7.62 | 3.75 | 0.63 | 4.00 | TH | 155,000 | 33.00 | |

| JKB984 | I | 7.000 | 2.50 | 5.00 | CH | 1.38 | CIH | 7.35 | 3.75 | 0.62 | 4.00 | TH | 155,000 | 33.00 | |

| JKB886 | V | 7.000 | 2.63 | 4.25 | CH | 1.63 | CIH | 6.79 | 2.75 | 0.75 | 4.00 | TH | 255,000 | 42.00 | |

| JKB4671 | I | 9.000 | 1.75 | 4.35 | CH | 1.00 | CIH | 6.21 | 3.38 | 0.50 | 3.00 | TH | 91,000 | 14.60 | |

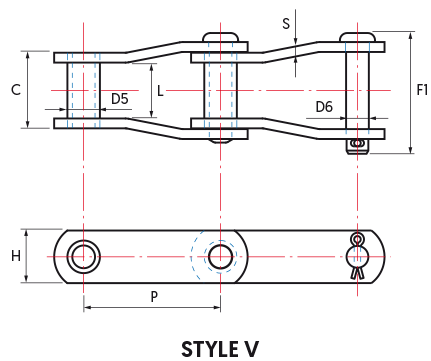

M Series metric conveyor chains

| M Series Metric Conveyor Chains | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain Number |

Pitch | Rollers | Bushings | Pins | Over All Pin & Cotter | Between Sidebars |

Sidebars | Breaking Load | |||||||

| Style | Flange Thickness |

Diameter | Thickness | Height | |||||||||||

| P | D1 | D2 | D4 | G | D5 | D6 | F1 | F2 | L | S | H | DIN standard |

John King* | ||

| mm | kN | ||||||||||||||

| M80 | 80 | 25 | 50 | 60 | 7 | 18 | 12 | 54.5 | 32 | 28 | 5 | 35 | 80 | 125 | |

| M80 | 100 | 25 | 50 | 60 | 7 | 18 | 12 | 54.5 | 32 | 28 | 5 | 35 | 80 | 125 | |

| M80 | 125 | 25 | 50 | 60 | 7 | 18 | 12 | 54.5 | 32 | 28 | 5 | 35 | 80 | 125 | |

| M80 | 160 | 25 | 50 | 60 | 7 | 18 | 12 | 54.5 | 32 | 28 | 5 | 35 | 80 | 125 | |

| M80 | 200 | 25 | 50 | 60 | 7 | 18 | 12 | 54.5 | 32 | 28 | 5 | 35 | 80 | 125 | |

| M112 | 80 | 30 | 60 | 75 | 7.5 | 21 | 15 | 66 | 35 | 32 | 6 | 40 | 112 | 175 | |

| M112 | 100 | 30 | 60 | 75 | 7.5 | 21 | 15 | 66 | 35 | 32 | 6 | 40 | 112 | 175 | |

| M112 | 125 | 30 | 60 | 75 | 7.5 | 21 | 15 | 66 | 35 | 32 | 6 | 40 | 112 | 175 | |

| M112 | 160 | 30 | 60 | 75 | 7.5 | 21 | 15 | 66 | 35 | 32 | 6 | 40 | 112 | 175 | |

| M112 | 200 | 30 | 60 | 75 | 7.5 | 21 | 15 | 66 | 35 | 32 | 6 | 40 | 112 | 175 | |

| M160 | 100 | 36 | 70 | 90 | 8.5 | 25 | 18 | 72 | 43 | 37 | 7 | 50 | 160 | 260 | |

| M160 | 125 | 36 | 70 | 90 | 8.5 | 25 | 18 | 72 | 43 | 37 | 7 | 50 | 160 | 260 | |

| M160 | 160 | 36 | 70 | 90 | 8.5 | 25 | 18 | 72 | 43 | 37 | 7 | 50 | 160 | 260 | |

| M160 | 200 | 36 | 70 | 90 | 8.5 | 25 | 18 | 72 | 43 | 37 | 7 | 50 | 160 | 260 | |

| M160 | 250 | 36 | 70 | 90 | 8.5 | 25 | 18 | 72 | 43 | 37 | 7 | 50 | 160 | 260 | |

| M224 | 125 | 42 | 85 | 100 | 10 | 30 | 21 | 88 | 47 | 43 | 8 | 60 | 224 | 340 | |

| M224 | 160 | 42 | 85 | 100 | 10 | 30 | 21 | 88 | 47 | 43 | 8 | 60 | 224 | 340 | |

| M224 | 200 | 42 | 85 | 100 | 10 | 30 | 21 | 88 | 47 | 43 | 8 | 60 | 224 | 340 | |

| M224 | 250 | 42 | 85 | 100 | 10 | 30 | 21 | 88 | 47 | 43 | 8 | 60 | 224 | 340 | |

| M224 | 315 | 42 | 85 | 100 | 10 | 30 | 21 | 88 | 47 | 43 | 8 | 60 | 224 | 340 | |

| M315 | 160 | 50 | 100 | 120 | 12 | 36 | 25 | 102 | 55 | 48 | 10 | 70 | 315 | 520 | |

| M315 | 200 | 50 | 100 | 120 | 12 | 36 | 25 | 102 | 55 | 48 | 10 | 70 | 315 | 520 | |

| M315 | 250 | 50 | 100 | 120 | 12 | 36 | 25 | 102 | 55 | 48 | 10 | 70 | 315 | 520 | |

| M315 | 315 | 50 | 100 | 120 | 12 | 36 | 25 | 102 | 55 | 48 | 10 | 70 | 315 | 520 | |

| M315 | 400 | 50 | 100 | 120 | 12 | 36 | 25 | 102 | 55 | 48 | 10 | 70 | 315 | 520 | |

| M450 | 200 | 60 | 120 | 140 | 14 | 42 | 30 | 118 | 66 | 56 | 12 | 80 | 450 | 700 | |

| M450 | 250 | 60 | 120 | 140 | 14 | 42 | 30 | 118 | 66 | 56 | 12 | 80 | 450 | 700 | |

| M450 | 315 | 60 | 120 | 140 | 14 | 42 | 30 | 118 | 66 | 56 | 12 | 80 | 450 | 700 | |

| M450 | 400 | 60 | 120 | 140 | 14 | 42 | 30 | 118 | 66 | 56 | 12 | 80 | 450 | 700 | |

| M630 | 250 | 70 | 140 | 170 | 16 | 50 | 36 | 138 | 74 | 66 | 14 | 100 | 630 | 1050 | |

| M630 | 315 | 70 | 140 | 170 | 16 | 50 | 36 | 138 | 74 | 66 | 14 | 100 | 630 | 1050 | |

| M630 | 400 | 70 | 140 | 170 | 16 | 50 | 36 | 138 | 74 | 66 | 14 | 100 | 630 | 1050 | |

| M630 | 500 | 70 | 140 | 170 | 16 | 50 | 36 | 138 | 74 | 66 | 14 | 100 | 630 | 1050 | |

| M900 | 250 | 85 | 170 | 210 | 18 | 60 | 44 | 158 | 89 | 78 | 16 | 120 | 900 | 1250 | |

| M900 | 315 | 85 | 170 | 210 | 18 | 60 | 44 | 158 | 89 | 78 | 16 | 120 | 900 | 1250 | |

| M900 | 400 | 85 | 170 | 210 | 18 | 60 | 44 | 158 | 89 | 78 | 16 | 120 | 900 | 1250 | |

| M900 | 500 | 85 | 170 | 210 | 18 | 60 | 44 | 158 | 89 | 78 | 16 | 120 | 900 | 1250 | |

| M Series Metric Conveyor Chains | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain Number |

Pitch | Rollers | Bushings | Pins | Over All Pin & Cotter | Between Sidebars |

Sidebars | Breaking Load | |||||||

| Style | Flange Thickness |

Diameter | Thickness | Height | |||||||||||

| P | D1 | D2 | D4 | G | D5 | D6 | F1 | F2 | L | S | H | DIN standard |

John King* | ||

| mm | kN | ||||||||||||||

| M80 | 80 | 25 | 50 | 60 | 7 | 18 | 12 | 54.5 | 32 | 28 | 5 | 35 | 80 | 125 | |

| M80 | 100 | 25 | 50 | 60 | 7 | 18 | 12 | 54.5 | 32 | 28 | 5 | 35 | 80 | 125 | |

| M80 | 125 | 25 | 50 | 60 | 7 | 18 | 12 | 54.5 | 32 | 28 | 5 | 35 | 80 | 125 | |

| M80 | 160 | 25 | 50 | 60 | 7 | 18 | 12 | 54.5 | 32 | 28 | 5 | 35 | 80 | 125 | |

| M80 | 200 | 25 | 50 | 60 | 7 | 18 | 12 | 54.5 | 32 | 28 | 5 | 35 | 80 | 125 | |

| M112 | 80 | 30 | 60 | 75 | 7.5 | 21 | 15 | 66 | 35 | 32 | 6 | 40 | 112 | 175 | |

| M112 | 100 | 30 | 60 | 75 | 7.5 | 21 | 15 | 66 | 35 | 32 | 6 | 40 | 112 | 175 | |

| M112 | 125 | 30 | 60 | 75 | 7.5 | 21 | 15 | 66 | 35 | 32 | 6 | 40 | 112 | 175 | |

| M112 | 160 | 30 | 60 | 75 | 7.5 | 21 | 15 | 66 | 35 | 32 | 6 | 40 | 112 | 175 | |

| M112 | 200 | 30 | 60 | 75 | 7.5 | 21 | 15 | 66 | 35 | 32 | 6 | 40 | 112 | 175 | |

| M160 | 100 | 36 | 70 | 90 | 8.5 | 25 | 18 | 72 | 43 | 37 | 7 | 50 | 160 | 260 | |

| M160 | 125 | 36 | 70 | 90 | 8.5 | 25 | 18 | 72 | 43 | 37 | 7 | 50 | 160 | 260 | |

| M160 | 160 | 36 | 70 | 90 | 8.5 | 25 | 18 | 72 | 43 | 37 | 7 | 50 | 160 | 260 | |

| M160 | 200 | 36 | 70 | 90 | 8.5 | 25 | 18 | 72 | 43 | 37 | 7 | 50 | 160 | 260 | |

| M160 | 250 | 36 | 70 | 90 | 8.5 | 25 | 18 | 72 | 43 | 37 | 7 | 50 | 160 | 260 | |

| M224 | 125 | 42 | 85 | 100 | 10 | 30 | 21 | 88 | 47 | 43 | 8 | 60 | 224 | 340 | |

| M224 | 160 | 42 | 85 | 100 | 10 | 30 | 21 | 88 | 47 | 43 | 8 | 60 | 224 | 340 | |

| M224 | 200 | 42 | 85 | 100 | 10 | 30 | 21 | 88 | 47 | 43 | 8 | 60 | 224 | 340 | |

| M224 | 250 | 42 | 85 | 100 | 10 | 30 | 21 | 88 | 47 | 43 | 8 | 60 | 224 | 340 | |

| M224 | 315 | 42 | 85 | 100 | 10 | 30 | 21 | 88 | 47 | 43 | 8 | 60 | 224 | 340 | |

| M315 | 160 | 50 | 100 | 120 | 12 | 36 | 25 | 102 | 55 | 48 | 10 | 70 | 315 | 520 | |

| M315 | 200 | 50 | 100 | 120 | 12 | 36 | 25 | 102 | 55 | 48 | 10 | 70 | 315 | 520 | |

| M315 | 250 | 50 | 100 | 120 | 12 | 36 | 25 | 102 | 55 | 48 | 10 | 70 | 315 | 520 | |

| M315 | 315 | 50 | 100 | 120 | 12 | 36 | 25 | 102 | 55 | 48 | 10 | 70 | 315 | 520 | |

| M315 | 400 | 50 | 100 | 120 | 12 | 36 | 25 | 102 | 55 | 48 | 10 | 70 | 315 | 520 | |

| M450 | 200 | 60 | 120 | 140 | 14 | 42 | 30 | 118 | 66 | 56 | 12 | 80 | 450 | 700 | |

| M450 | 250 | 60 | 120 | 140 | 14 | 42 | 30 | 118 | 66 | 56 | 12 | 80 | 450 | 700 | |

| M450 | 315 | 60 | 120 | 140 | 14 | 42 | 30 | 118 | 66 | 56 | 12 | 80 | 450 | 700 | |

| M450 | 400 | 60 | 120 | 140 | 14 | 42 | 30 | 118 | 66 | 56 | 12 | 80 | 450 | 700 | |

| M630 | 250 | 70 | 140 | 170 | 16 | 50 | 36 | 138 | 74 | 66 | 14 | 100 | 630 | 1050 | |

| M630 | 315 | 70 | 140 | 170 | 16 | 50 | 36 | 138 | 74 | 66 | 14 | 100 | 630 | 1050 | |

| M630 | 400 | 70 | 140 | 170 | 16 | 50 | 36 | 138 | 74 | 66 | 14 | 100 | 630 | 1050 | |

| M630 | 500 | 70 | 140 | 170 | 16 | 50 | 36 | 138 | 74 | 66 | 14 | 100 | 630 | 1050 | |

| M900 | 250 | 85 | 170 | 210 | 18 | 60 | 44 | 158 | 89 | 78 | 16 | 120 | 900 | 1250 | |

| M900 | 315 | 85 | 170 | 210 | 18 | 60 | 44 | 158 | 89 | 78 | 16 | 120 | 900 | 1250 | |

| M900 | 400 | 85 | 170 | 210 | 18 | 60 | 44 | 158 | 89 | 78 | 16 | 120 | 900 | 1250 | |

| M900 | 500 | 85 | 170 | 210 | 18 | 60 | 44 | 158 | 89 | 78 | 16 | 120 | 900 | 1250 | |

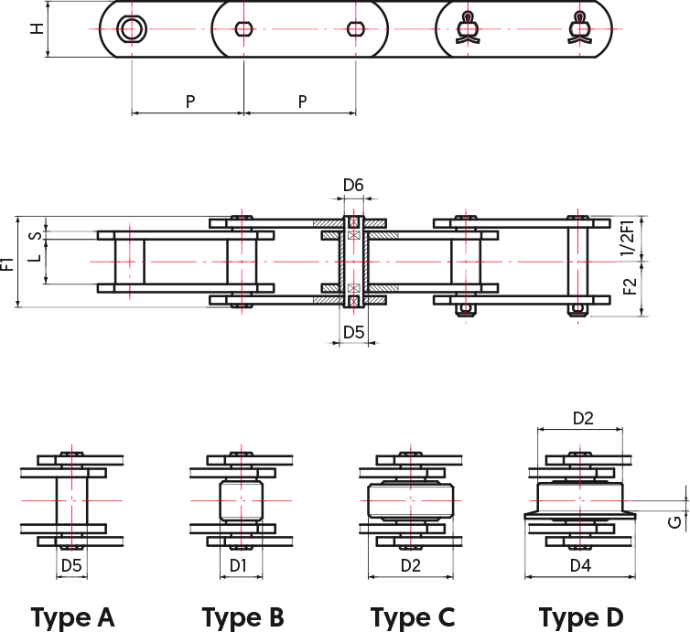

FV Series metric conveyor chains

| FV Series Metric Conveyor Chains | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain Number |

Pitch | Rollers | Bushings | Pins | Over All Pin & Cotter | Between Sidebars |

Sidebars | Breaking Load | ||||||||

| Style | Flange Thickness |

Diameter | Thickness | Height | ||||||||||||

| P | D1 | D2 | D3 | D4 | G | D5 | D6 | F1 | F2 | L | S | H | DIN standard |

John King* | ||

| mm | kN | |||||||||||||||

| FV63 | 63 | 26 | 40 | 50 | 63 | 5 | 18 | 12 | 45 | 26 | 22 | 4 | 30 | 64 | 75 | |

| FV63 | 80 | 26 | 40 | 50 | 63 | 5 | 18 | 12 | 45 | 26 | 22 | 4 | 30 | 64 | 75 | |

| FV63 | 100 | 26 | 40 | 50 | 63 | 5 | 18 | 12 | 45 | 26 | 22 | 4 | 30 | 64 | 75 | |

| FV63 | 125 | 26 | 40 | 50 | 63 | 5 | 18 | 12 | 45 | 26 | 22 | 4 | 30 | 64 | 75 | |

| FV63 | 160 | 26 | 40 | 50 | 63 | 5 | 18 | 12 | 45 | 26 | 22 | 4 | 30 | 64 | 75 | |

| FV90 | 63 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV90 | 80 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV90 | 100 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV90 | 125 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV90 | 160 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV90 | 200 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV90 | 250 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV112 | 100 | 32 | 55 | 72 | 90 | 7.5 | 22 | 16 | 62 | 35 | 30 | 6 | 40 | 120 | 170 | |

| FV112 | 125 | 32 | 55 | 72 | 90 | 7.5 | 22 | 16 | 62 | 35 | 30 | 6 | 40 | 120 | 170 | |

| FV112 | 160 | 32 | 55 | 72 | 90 | 7.5 | 22 | 16 | 62 | 35 | 30 | 6 | 40 | 120 | 170 | |

| FV112 | 200 | 32 | 55 | 72 | 90 | 7.5 | 22 | 16 | 62 | 35 | 30 | 6 | 40 | 120 | 170 | |

| FV112 | 250 | 32 | 55 | 72 | 90 | 7.5 | 22 | 16 | 62 | 35 | 30 | 6 | 40 | 120 | 170 | |

| FV140 | 100 | 36 | 60 | 80 | 100 | 9 | 26 | 18 | 67 | 41 | 35 | 6 | 45 | 145 | 180 | |

| FV140 | 125 | 36 | 60 | 80 | 100 | 9 | 26 | 18 | 67 | 41 | 35 | 6 | 45 | 145 | 180 | |

| FV140 | 160 | 36 | 60 | 80 | 100 | 9 | 26 | 18 | 67 | 41 | 35 | 6 | 45 | 145 | 180 | |

| FV140 | 200 | 36 | 60 | 80 | 100 | 9 | 26 | 18 | 67 | 41 | 35 | 6 | 45 | 145 | 180 | |

| FV140 | 250 | 36 | 60 | 80 | 100 | 9 | 26 | 18 | 67 | 41 | 35 | 6 | 45 | 145 | 180 | |

| FV Series Metric Conveyor Chains | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain Number |

Pitch | Rollers | Bushings | Pins | Over All Pin & Cotter | Between Sidebars |

Sidebars | Breaking Load | ||||||||

| Style | Flange Thickness |

Diameter | Thickness | Height | ||||||||||||

| P | D1 | D2 | D3 | D4 | G | D5 | D6 | F1 | F2 | L | S | H | DIN standard |

John King* | ||

| mm | kN | |||||||||||||||

| FV63 | 63 | 26 | 40 | 50 | 63 | 5 | 18 | 12 | 45 | 26 | 22 | 4 | 30 | 64 | 75 | |

| FV63 | 80 | 26 | 40 | 50 | 63 | 5 | 18 | 12 | 45 | 26 | 22 | 4 | 30 | 64 | 75 | |

| FV63 | 100 | 26 | 40 | 50 | 63 | 5 | 18 | 12 | 45 | 26 | 22 | 4 | 30 | 64 | 75 | |

| FV63 | 125 | 26 | 40 | 50 | 63 | 5 | 18 | 12 | 45 | 26 | 22 | 4 | 30 | 64 | 75 | |

| FV63 | 160 | 26 | 40 | 50 | 63 | 5 | 18 | 12 | 45 | 26 | 22 | 4 | 30 | 64 | 75 | |

| FV90 | 63 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV90 | 80 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV90 | 100 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV90 | 125 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV90 | 160 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV90 | 200 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV90 | 250 | 30 | 48 | 63 | 78 | 6.5 | 20 | 14 | 53 | 30 | 25 | 5 | 35 | 100 | 115 | |

| FV112 | 100 | 32 | 55 | 72 | 90 | 7.5 | 22 | 16 | 62 | 35 | 30 | 6 | 40 | 120 | 170 | |

| FV112 | 125 | 32 | 55 | 72 | 90 | 7.5 | 22 | 16 | 62 | 35 | 30 | 6 | 40 | 120 | 170 | |

| FV112 | 160 | 32 | 55 | 72 | 90 | 7.5 | 22 | 16 | 62 | 35 | 30 | 6 | 40 | 120 | 170 | |

| FV112 | 200 | 32 | 55 | 72 | 90 | 7.5 | 22 | 16 | 62 | 35 | 30 | 6 | 40 | 120 | 170 | |

| FV112 | 250 | 32 | 55 | 72 | 90 | 7.5 | 22 | 16 | 62 | 35 | 30 | 6 | 40 | 120 | 170 | |

| FV140 | 100 | 36 | 60 | 80 | 100 | 9 | 26 | 18 | 67 | 41 | 35 | 6 | 45 | 145 | 180 | |

| FV140 | 125 | 36 | 60 | 80 | 100 | 9 | 26 | 18 | 67 | 41 | 35 | 6 | 45 | 145 | 180 | |

| FV140 | 160 | 36 | 60 | 80 | 100 | 9 | 26 | 18 | 67 | 41 | 35 | 6 | 45 | 145 | 180 | |

| FV140 | 200 | 36 | 60 | 80 | 100 | 9 | 26 | 18 | 67 | 41 | 35 | 6 | 45 | 145 | 180 | |

| FV140 | 250 | 36 | 60 | 80 | 100 | 9 | 26 | 18 | 67 | 41 | 35 | 6 | 45 | 145 | 180 | |

Welded steel chains

| Offset Sidebar Welded Steel Chains | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain Number |

Pitch | Bushings | Rivets | Over-All Pin & Cotter |

Between Sidebars |

Length of Bearing | Sidebars | Breaking Load |

Average Weight |

||

| Outside Diameter | Diameter | Thickness | Height | ||||||||

| P | D5 | D6 | F1 | L | S | H | |||||

| inches | lbs | lbs/ft | |||||||||

| WH78/R | 2.609 | 0.84 | 0.50 | 3.00 | 1.00 | 2.00 | 0.25 | 1.25 | 33,000 | 4.30 | |

| WH82/R | 3.075 | 1.00 | 0.56 | 3.38 | 1.13 | 2.25 | 0.25 | 1.25 | 36,000 | 4.70 | |

| WH124/R | 4.000 | 1.25 | 0.75 | 4.25 | 1.50 | 2.75 | 0.38 | 1.50 | 57,000 | 7.80 | |

| WH111/R | 4.760 | 1.25 | 0.75 | 4.81 | 1.75 | 3.38 | 0.38 | 1.75 | 60,000 | 8.60 | |

| WH110/R | 6.000 | 1.25 | 0.75 | 4.00 | 1.88 | 3.00 | 0.38 | 1.50 | 50,500 | 7.00 | |

| WH106/R | 6.000 | 1.25 | 0.75 | 4.25 | 1.50 | 2.75 | 0.38 | 1.50 | 60,000 | 6.20 | |

| WH132/R | 6.050 | 1.75 | 1.00 | 6.38 | 2.75 | 4.41 | 0.50 | 2.00 | 122,000 | 14.10 | |

| WH150/R | 6.050 | 1.75 | 1.00 | 6.50 | 2.75 | 4.41 | 0.50 | 2.50 | 122,000 | 16.30 | |

| WH155/R | 6.050 | 1.75 | 1.13 | 6.41 | 2.75 | 4.41 | 0.56 | 2.50 | 175,000 | 19.00 | |

| WH157/R | 6.050 | 1.75 | 1.13 | 6.75 | 2.75 | 4.63 | 0.63 | 2.50 | 175,000 | 20.00 | |

| WH159/R | 6.125 | 2.00 | 1.25 | 6.75 | 2.75 | 4.63 | 0.63 | 3.00 | 210,000 | 26.00 | |

| WH200/R | 6.125 | 2.00 | 1.25 | 6.75 | 2.75 | 4.63 | 0.63 | 2.50 | 190,000 | 22.10 | |

| Offset Sidebar Welded Steel Chains | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Chain Number |

Pitch | Bushings | Rivets | Over-All Pin & Cotter |

Between Sidebars |

Length of Bearing | Sidebars | Breaking Load |

Average Weight |

||

| Outside Diameter | Diameter | Thickness | Height | ||||||||

| P | D5 | D6 | F1 | L | S | H | |||||

| inches | lbs | lbs/ft | |||||||||

| WH78/R | 2.609 | 0.84 | 0.50 | 3.00 | 1.00 | 2.00 | 0.25 | 1.25 | 33,000 | 4.30 | |

| WH82/R | 3.075 | 1.00 | 0.56 | 3.38 | 1.13 | 2.25 | 0.25 | 1.25 | 36,000 | 4.70 | |

| WH124/R | 4.000 | 1.25 | 0.75 | 4.25 | 1.50 | 2.75 | 0.38 | 1.50 | 57,000 | 7.80 | |

| WH111/R | 4.760 | 1.25 | 0.75 | 4.81 | 1.75 | 3.38 | 0.38 | 1.75 | 60,000 | 8.60 | |

| WH110/R | 6.000 | 1.25 | 0.75 | 4.00 | 1.88 | 3.00 | 0.38 | 1.50 | 50,500 | 7.00 | |

| WH106/R | 6.000 | 1.25 | 0.75 | 4.25 | 1.50 | 2.75 | 0.38 | 1.50 | 60,000 | 6.20 | |

| WH132/R | 6.050 | 1.75 | 1.00 | 6.38 | 2.75 | 4.41 | 0.50 | 2.00 | 122,000 | 14.10 | |

| WH150/R | 6.050 | 1.75 | 1.00 | 6.50 | 2.75 | 4.41 | 0.50 | 2.50 | 122,000 | 16.30 | |

| WH155/R | 6.050 | 1.75 | 1.13 | 6.41 | 2.75 | 4.41 | 0.56 | 2.50 | 175,000 | 19.00 | |

| WH157/R | 6.050 | 1.75 | 1.13 | 6.75 | 2.75 | 4.63 | 0.63 | 2.50 | 175,000 | 20.00 | |

| WH159/R | 6.125 | 2.00 | 1.25 | 6.75 | 2.75 | 4.63 | 0.63 | 3.00 | 210,000 | 26.00 | |

| WH200/R | 6.125 | 2.00 | 1.25 | 6.75 | 2.75 | 4.63 | 0.63 | 2.50 | 190,000 | 22.10 | |