HAZARD MONITORING SYSTEM AND SAFETY MEASURES

Our partner, STIF, has developed a comprehensive monitoring system to enhance equipment safety and protect personnel, drawing on extensive experience in the storage and transportation of bulk materials.

The system provides continuous monitoring, equipment operation management, performance data recording and analysis, as well as rapid fault detection.

JET SYSTEM: The Smart Way to Manage Safety Systems

JET SYSTEM is an intelligent solution for full safety control of conveyors and elevators, minimizing risks and preventing hazardous situations such as speed reduction, misalignment, overloading and blockages, as well as overheating of bearings and motors—key risk factors for explosions.

The system instantly alerts users to equipment malfunctions and performance issues, sending notifications directly to your laptop, tablet, or smartphone, allowing you to manage your facility from anywhere in the world. In this way, JET SYSTEM ensures smooth operation, reduces downtime, and enhances overall production efficiency.

Conveyor and Elevator Hazard Monitoring and Control System

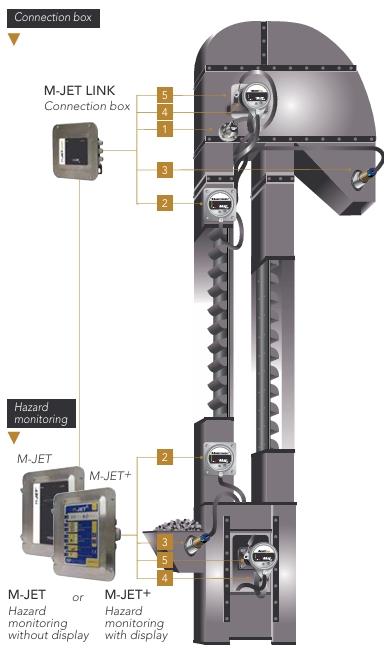

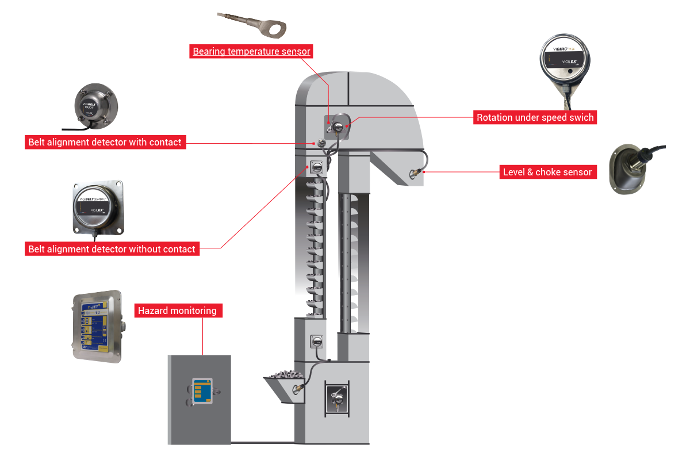

Our hazard monitoring devices can manage the operation of bucket elevators, belt, chain, and screw conveyors. The system analyzes data from sensors installed on the equipment to detect potential faults. Depending on the settings, M-JET+ or M-JET sends alarm signals and can control conveyor shutdown.

M-JET+ and M-JET monitor the following parameters:

Speed Reduction: Detects slipping of the belt on the pulley by comparing it to the nominal speed.

Bearing Temperature: Monitored using PT100 or NTC sensors.

Belt Misalignment: Identified with contact or non-contact sensors.

Material Jamming: Monitored at the conveyor’s input or output using capacitive sensors.

Chain Elongation: Measured with an inductive sensor and targets.

Motor Power Measurement: Monitors specific electrical consumption.

Shaft Position: Measured by a 4-20 mA sensor.

Control of the system operation is carried out through output relays:

Directly to the motor's power relay.

Through the global PLC of the installations.

Conveyor operation can be checked via:

A computer screen using an internal website (directly from a laptop or through a LAN network).

Email notifications (event information and maintenance schedule).