Вибухозахист

In industry, aspiration is associated with the movement of air or gas through ventilation systems to remove contaminants such as dust and fumes. Flammable gases, liquids, and fine particles increase the risk of explosions at certain concentrations. Sparks or flames can trigger hazardous explosions.

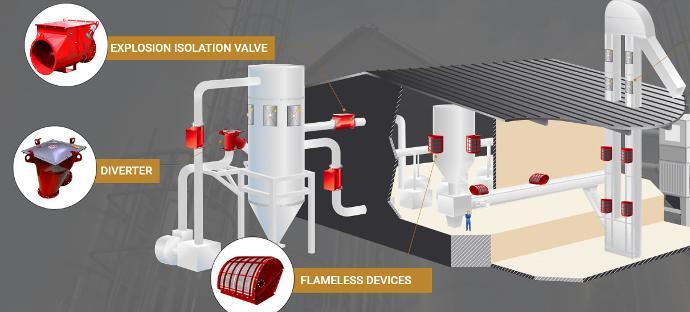

Explosions are more common in sectors where flammable materials are processed, particularly in the chemical, food, and metallurgy industries. To reduce risks, explosion protection systems are employed to vent pressure and dust, ensuring the safety of personnel and equipment.

What is a Dust Explosion and What is an Explosion Protection System?

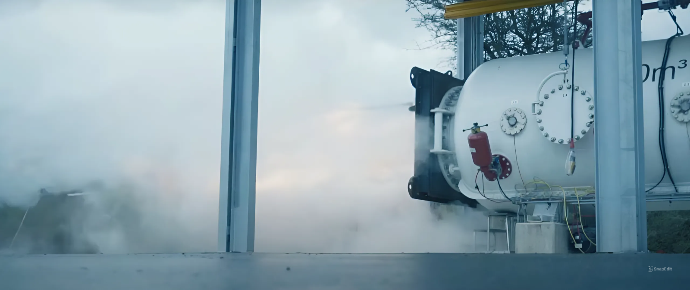

A dust explosion occurs when a spark ignites combustible dust or fuel, leading to instantaneous combustion. This phenomenon creates a massive cloud of gas or dust that is released into the surrounding environment. It is important to note that an open flame is not necessary for an explosion to occur; various ignition sources can trigger this hazardous situation. When the internal pressure in a container becomes too high, it can result in an explosion.

Explosion protection is one of the most common and effective methods of ensuring safety in industry. It reduces excessive pressure generated during an explosion and provides a controlled path for the release of expanding gases.

It helps limit excessive pressure that occurs during an explosion by releasing unburned fuel mixtures and combustion products.

Vent panels do not prevent explosions; they assist in managing and controlling the maximum pressure within the vessel.

These panels serve as indispensable pressure relief valves, directing the explosion's energy outside the vessel.

Explosion protection systems are designed to fail safely at a predetermined pressure, ensuring safety and minimizing damage.

The VIGILEX ventilation valves, developed by STIF, meet all necessary health and safety standards, ensuring their suitability for use in environments with explosive atmospheric conditions (Directive 94/9/EC). These systems provide reliable protection and effective ventilation, making them ideal for application in industries where there is a risk of explosions.

Additional certifications:

Ex II GD

EN 14491

EN 14994

EN 14797

EN 1127.1

EU Type Examination Certificate: INERIS 15ATEX0001X

Production Quality Assurance Notification: INERIS 08ATEXQ406

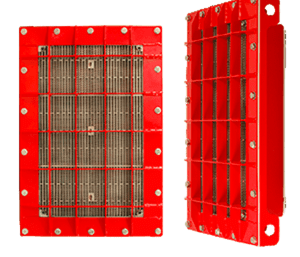

VIGIFLAM Vi

The VIGIFLAM Vi flameproof ventilation device has a rectangular shape and consists of three main components: the housing, a metallic filter made of multiple layers for cooling the flame, and a new innovative explosion-proof panel. This stainless steel membrane features a weakened area in the center, allowing it to rupture when excessive pressure occurs inside the protected equipment.