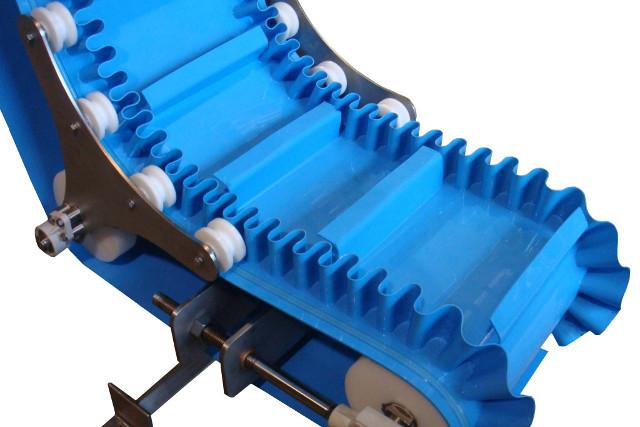

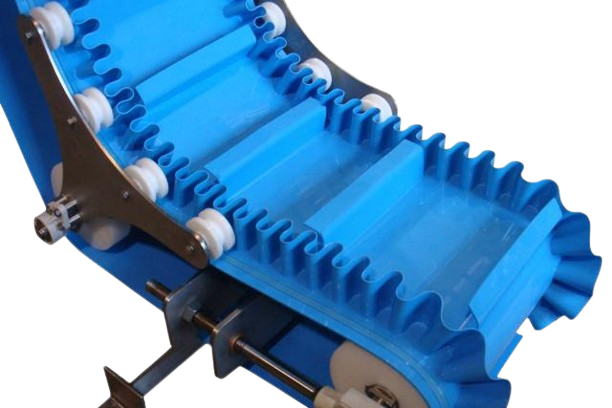

VOLTA HOMOGENEOUS PU BELTS

According to HACCP requirements, the materials used for manufacturing equipment must be suitable for contact with specific products, surrounding conditions, cleaning and disinfecting agents, as well as the sanitation methods applied. The use of fabric elements in the construction is not allowed, as fabric absorbs moisture and serves as a breeding ground for microorganisms. The main disadvantage of belts with fabric cords is delamination, fraying of the cord, and wear of the polymer coating. Delamination and wear of the fabric layers directly affect the lifespan of the belt and the level of hygiene in both the technological lines and the products produced.

Volta Belting Conveyor Belts for the Food Industry

Volta Belting conveyor belts for the food industry comply with HACCP requirements. These belts feature a specially designed homogeneous structure and are made from unique TPU materials. They are manufactured with materials that are resistant to cuts and abrasion, thereby eliminating the risk of nicks and scratches where bacteria can thrive and multiply. This significantly simplifies cleaning and leads to reduced labor costs and decreased production downtime.

The ease of cleaning the belts contributes to:

Reduced water and detergent consumption, as well as lower waste discharge;

Decreased disinfection costs;

Reduced production downtime;

Increased shelf life of finished products;

Lower probability of costly product recalls.

Additionally, Volta belts are characterized by high durability, achieved by the absence of fabric layers that could become contaminated or delaminate, along with a robust, wear-resistant surface that prevents contamination. They also exhibit high resistance to hydrolysis, oils, and chemicals, allowing the belts to maintain their elasticity for many years. Their cut and abrasion resistance enables the use of these belts for cutting products.