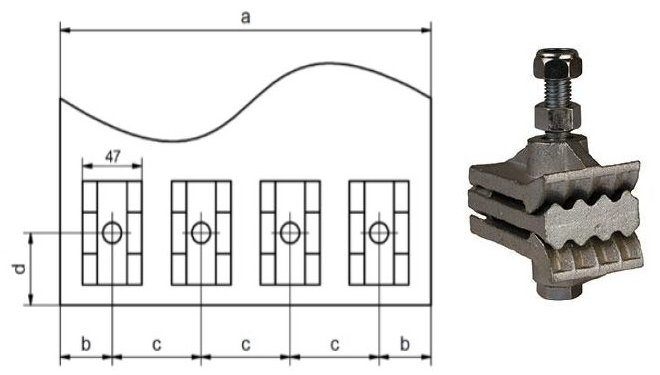

MECHANICAL BELT CONNECTORS

Mechanical belt connectors ensure smooth operation and high reliability.

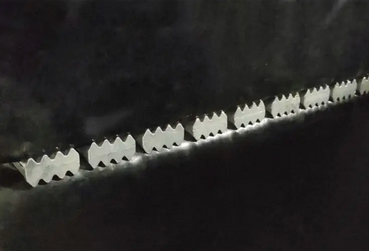

The connection point is the weakest link, so the method of belt splicing deserves special attention. Mechanical connectors are a modern, reliable splicing method recommended by leading manufacturers of equipment and elevator belts. This type of connection offers several advantages, including smoother belt movement, reduced wear, and a higher level of reliability compared to overlap joints.

Economic Advantages of Mechanical Belt Connectors

From an economic perspective, mechanical connectors reduce the cost of belt splicing by requiring less belt length and fewer labor hours for installation.

Due to the standardization of work and installation processes on elevators, mechanical connectors are the simplest, most versatile, convenient, and reliable splicing method.

With overlap splicing, material can get lodged in the splice area, especially with sticky, greasy, or fine materials. Overlapping splices also lead to inevitable impact as the splice hits the drum, which can cause pieces of the belt to chip, belt oscillation, and additional strain on bearings and shafts.

Using makeshift clamping plates often results in the belt bending at a sharp angle rather than a smooth radius, increasing the risk of breakage due to stress concentration.

Our solution provides a high-quality, reliable connection for all bucket elevator belts in your facility.