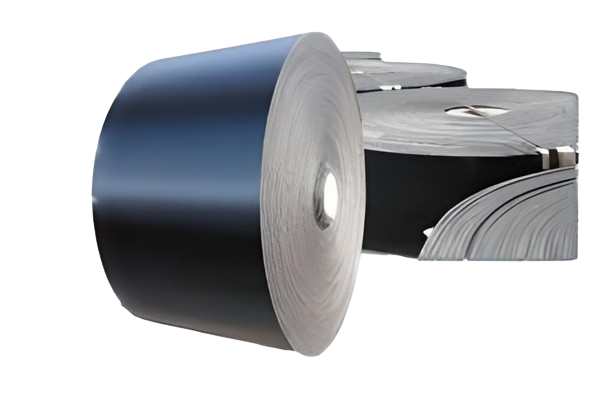

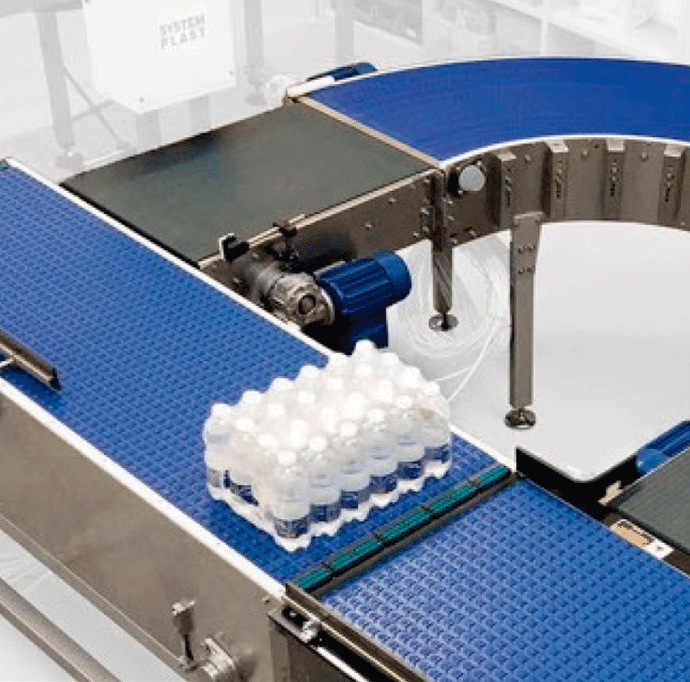

SYSTEM PLAST MODULAR BELTS

SYSTEM PLAST produces a wide range of modular belts with different steps (from 12.7 mm to 63.5 mm), with different types of surface, from various materials, which, thanks to the variety of technical characteristics, can be used in various industries.

Among the main types of modular belts can be distinguished:

Straight modular belts

Turning modular belts

Belts with open and closed surface types

Belts with rubber inserts

Belts with LBP rollers

Belts with various accessories (side rails, partitions, etc.)

SYSTEM PLAST Modular Belts: Materials and Advantages

SYSTEM PLAST modular belts can be made from various materials, the main ones being acetal in white, blue, and gray colors (LFW, LFB, LFG), polypropylene (PP, PPW, PPG, PPLG), and the modern NGE polymer (New Generation EVO).

The advantage of the NGE material is that it includes a solid lubricant in its molecular structure, allowing modular belts made from it to be used without external lubrication. In addition to the benefits provided by the absence of lubrication, the customer also experiences a reduction in overall noise levels, decreased friction, the ability to operate at higher speeds, and at higher temperatures (up to 120°C).

In addition to standard materials, there is the option to use special anti-static materials AS / POM-AS, high-temperature materials HT (for temperatures up to 140°C), materials with increased wear resistance DK, electroconductive POM-EC, and fire-resistant materials PP-FR-EC.

SYSTEM PLAST manufactures both straight-running and turning modular belts in the following series: 2120, 2122, 2121, 2123, 2124, 2190, 2250, 2253, 2251, 2252, 2500, 2508, 2630, 21220M, 2250FG, 2250TAB, 2260, 2251TAB, 2256FG, 2256C, 2351, 2351TAB, 2551, 2551TAB, 2451TAB, 2651TAB.

As an option, cross partitions (flights) of varying heights, pitches, and configurations can be installed on the belts of the 2250 series.

In addition to different series, the belts differ in surface types: Flat top (FT) – closed flat surface, Flush grid (FG) – partially open surface, Rubber inserts (VG) – with rubber inserts, LBP – surface with polymer rollers, Special Guide bar (GB) – surface with partitions, Roller top (RT) – new modular belts most suitable for product sorting.

For various application conditions, SYSTEM PLAST uses three types of pins in modular belts:

PBT (used in most belts made from LFG, XPG, AS, DK materials)

POM (polyacetal, most optimal for belts made from NGE materials)

PP (used with polypropylene belts and provides increased resistance to temperature and chemical exposure)