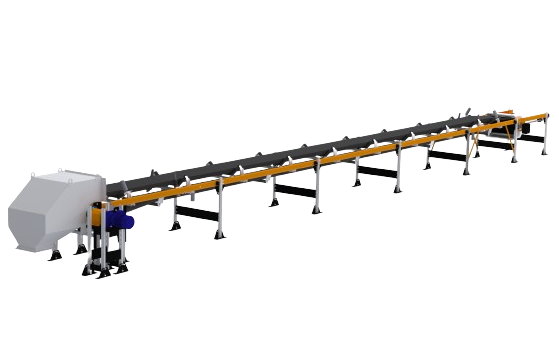

PLATE CONVEYOR CHAINS

Plate conveyor chains SYSTEM PLAST are various types of chains designed for different tasks in automation and transportation.

SYSTEM PLAST conveyor chains are of the following types:

Straight-running chains

Magnetic-turning loops

Turning chains with Tabs and Bevels

Chains with rubber inserts

Chains with LBP rollers on the outer surface

Gripper chains with rubber combs

Plastic chains based on rollers

Biplanar chains

Box chains

Advantages of Materials and Design of System Plast Conveyor Chains

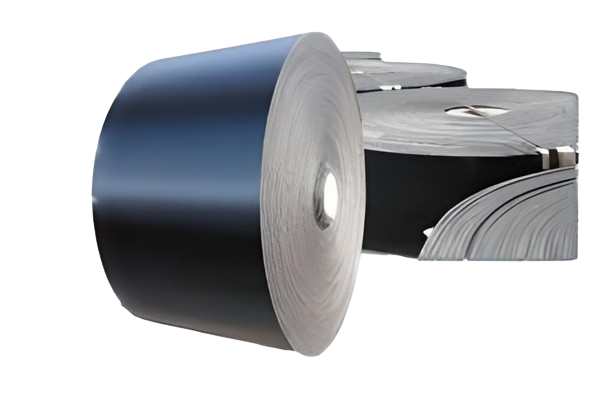

Conveyor chains can be manufactured from wear-resistant stainless steel of various grades or from a range of polymer materials.

The advantages of System Plast chains include improved beveled edges on the upper and lower parts of the plates, an enhanced hinge design, and minimal possible gaps between the plates. These features contribute to prolonged and stable equipment operation, reduce noise levels, and enhance the stability of the transported product.

For high-speed conveyors, steel chains from the SPEED LINE series can be effectively utilized. These chains may include vacuum-hardened, highly wear-resistant pins, which extend the chain's service life by more than twice.

For plastic plate chains operating at high speeds, it is recommended to use the new, advanced NGE polymer. This material incorporates a solid lubricant in its molecular structure, allowing the conveyor chains to operate without external lubrication. In addition to the benefits of lubrication-free operation, customers gain reduced overall noise levels, decreased friction, and the ability to work at higher speeds and elevated temperatures (up to 120°C).

System Plast Plate Conveyor Chain Series System Plast categorizes plate conveyor chains into the following series:

Steel Straight-Running Chains with Smooth Surfaces (STRAIGHT FLAT TOP): 812, 815, 812L, 815L, 800, 802, 805, 8157, 515.

Steel Straight-Running Chains with Rubber Inserts (STRAIGHT RUBBER TOP): 815VG, 815 VG TAB, 814VG, 8157VG, 8157 TAB VG, 805VG.

Steel Curved Chains with Smooth Surfaces (FLAT TOP): 881M, 881MO, 881 TAB, 8810 TAB, 881, 8810, 8857 TAB, 8857 M.

Steel Curved Chains with Rubber Inserts (RUBBER TOP): 881 MO VG, 8857 M VG, 881VG, 881 TAB VG.

Steel Curved Chains with Plate Tops Based on Roller Chains (¾” Pitch, 19.05 mm): Series 1874.

Curved Gripper Chains Based on Roller Chains: Series 1874 VG.

Plastic Straight-Running Chains with Various Surface Types (FLAT TOP, PLATE TOP Based on Roller Chains, RUBBER TOP with Rubber Inserts, and LBP Rollers): 820, 820P, 831, 828, 8257, 821, SK38, 843, 845, 863, 831 VG, 8257 VG, 821 VG, LBP 831, LBP 8257, LBP 821.

Plastic Curved Chains (FLAT TOP, PLATE TOP Based on Roller Chains, GRIPPER, RUBBER TOP with Rubber Inserts, and LBP Rollers): 879M, 880M, 877TAB, 878TAB, 879 TAB, 880 TAB, 879, 880, 8800P, 882 M, 882 BEVEL, 882 TAB, 1843 TAB, 1873 TAB, 1863 TAB, 879 M VG, 878 VG TAB, 879 TAB VG, 882 M VG, 882 TAB VG, 1873 TAB VG, 878 TAB GS, 1873 TAB GS, LBP 878 TAB, LBP 879 M, LBP 882 M, LBP 882 TAB.

Materials Used for Steel Plate Chains

Carbon Steel (C45): Suitable exclusively for use in dry environments.

Stainless Steel for Standard Applications (AISI 430): Ideal for general use.

Extra Plus Stainless Steel: Designed for high-speed conveyors and conveyors with heavy loads.

Austenitic Stainless Steel (AISI 304): Contains 18% chromium and 8% nickel, offering enhanced corrosion resistance and acid resistance.

System Plast plastic chains can be manufactured from various materials, primarily including acetal in white, blue, and gray colors (LFW, LFB, LFG), polypropylene (PP), and the modern NGE polymer (New Generation EVO).

In addition to standard materials, the following can be used upon the client's request: HT (for temperatures up to 140°C), DK (material with increased wear resistance), AR (abrasion-resistant polyamide), AS (anti-static acetal), and CR (chemically resistant polypropylene).

Three types of materials are used for connecting pins: SPM (standard option made of austenitic stainless steel), HB (vacuum-hardened stainless steel for particularly heavy-duty conditions), and PPM (plastic made of reinforced acetal).

Plate chains are manufactured in various widths and are selected based on operating conditions: K125, K250, K263, K300, K325, K330, K350, K400, K450, K600, K750, K1000, K1200.

In addition to the listed conveyor chains, System Plast's production program includes biplanar Multiflex chains and crate conveyor chains in the following series: 1700, 1702, 1701 TAB, 1706, 1710, 1710C TAB, CC600, CC600TAB, CC600P, CC600TAB P, CC600F, CC631 TAB, CC1400, CC1400TAB, CC1431TAB, CC1400V, CC1400V TAB.